AntarcticPilot

Well-known member

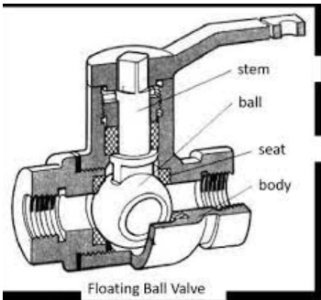

Just had an "interesting" failure of the seacock on my engine raw water inlet. Opened it to start the engine; it apparently worked smoothly and easily (too easily?). Started the engine - no water. Checked the water pump - all ok. Investigated the seacock - handle and spindle both rotating smoothly. Opened up the strainer, which is the cylindrical type vertically over the seacock, and found that no matter what the position of the handle, the seacock remained closed. This is obvious in my case as you can see daylight through the strainer when it's open! But I probed with a long screwdriver to ensure it wasn't blocked by fouling. Apparently somehow the spindle has become detached from the ball.

The seacock is new; it was replaced last year by a reputable yard; but of course they don't make the seacocks!

I'm curious about the following:

The seacock is new; it was replaced last year by a reputable yard; but of course they don't make the seacocks!

I'm curious about the following:

- How can the spindle become detached? After all, it worked fine when I closed the seacock!

- How common is this failure mode?

- How can it be avoided?