vas

Well-Known Member

I see that and raise you ?

on a serious note, this bleeding chain counter is one of the worst bits of code I've gone through.

Tested all winter last year with the boat in port and engines off, worked a treat.

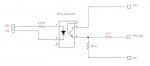

Throughout the season with engines obviously running, some electromagnetic noise was picked up somewhere and values are slow in dropping (or quick in retrieving, still to work that out!)

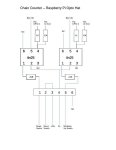

and reading you latest post, that's exactly how I'm dealing with up and down, imho the only way to do it! and I'm keeping current chain out in an sdcard so even if system reboots it will read the value from the sd and start where it should.

I'm lucky that garmin GMI10/20 are capable of presenting N0183 sentences of chain out (from an old AutoAnchor black box) so I'm viewing that on the f/b as the chain is dropped/retrieved.

V.

PS. grafana, presenting N2K data that go to my office server via signalK running on a raspberry onboard.

Last edited: