steveeasy

Well-known member

At long last I’ve got the boat in the water.lots of work and planned to set off in the morning for a weeks sailing. Had the mast off to fit a new ring and had a good check over all of the fittings.

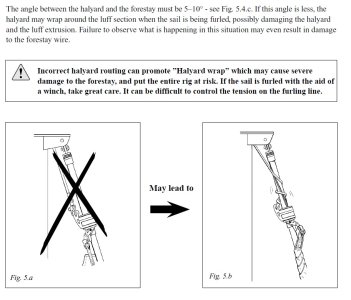

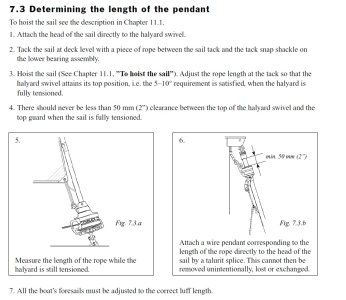

Wind dropped and tried to put the Genoa on. Got the thing on and the Furler won’t turn. Jammed solid. Pulled the Genoa off and she turns ok. The luff was not tensioned. I did check the top of the forestry when the rig was down. Looked fine no sign of twist.

The Furler is not that old. I’ve popped a couple of images up. They might just be the right orientation. And words of wisdom. No my Nickers are not twisted and I’m not having a hissy but round here you ask people to help sort stuff and the only response you get is, oh we don’t do that,or this or anything.

Can’t recal how the forestry attaches at top of mast.

Any idears

Steveeasy

Wind dropped and tried to put the Genoa on. Got the thing on and the Furler won’t turn. Jammed solid. Pulled the Genoa off and she turns ok. The luff was not tensioned. I did check the top of the forestry when the rig was down. Looked fine no sign of twist.

The Furler is not that old. I’ve popped a couple of images up. They might just be the right orientation. And words of wisdom. No my Nickers are not twisted and I’m not having a hissy but round here you ask people to help sort stuff and the only response you get is, oh we don’t do that,or this or anything.

Can’t recal how the forestry attaches at top of mast.

Any idears

Steveeasy