Hurricane

Well-Known Member

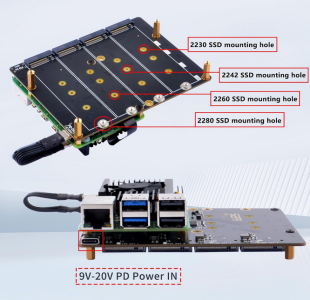

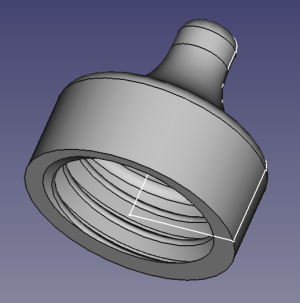

That particular model had a little more to it - a female thread to screw onto the salt pot.That’s firstly clever then obvious afterwards

Fairly early on, I learned how to use the Boolean process.

In 3D design, a Boolean process adds or subtracts material.

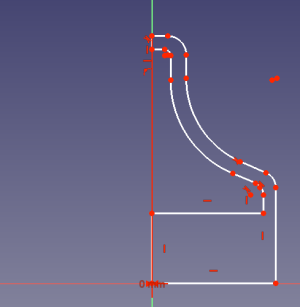

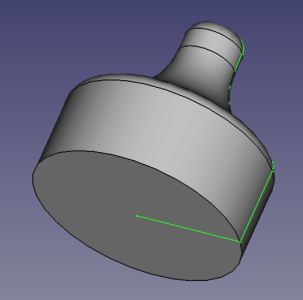

This was the original 2D sketch

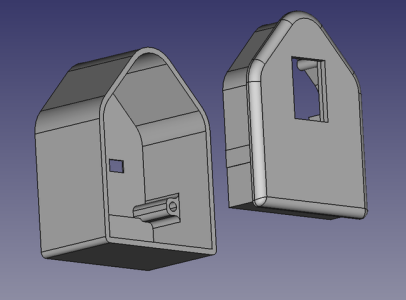

When rotated it turns into this solid - in fact there is a hollow space inside.

And then the thread is Boolean'd removing material to produce a female thread

In that case, I wasn't sure of the actual thread so I inserted something that looked correct.

Then a bit of measurement and trial/error on a test piece until it fitted.

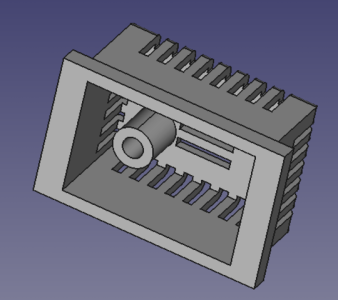

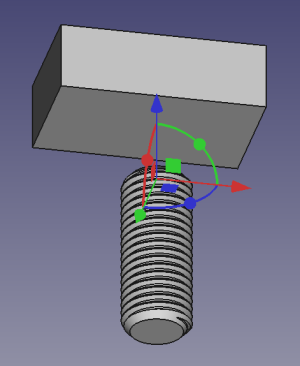

I didn't do it in the above case but most of the female threads that I've made, I make a male thread first as a separate part, then place it where I need it and then Boolean it out

Like this

There is probably a better way but this allows precise positioning of the thread.

As I say, I'm only a novice at this stuff.

But I am finding it all a lot of fun.