vas

Well-Known Member

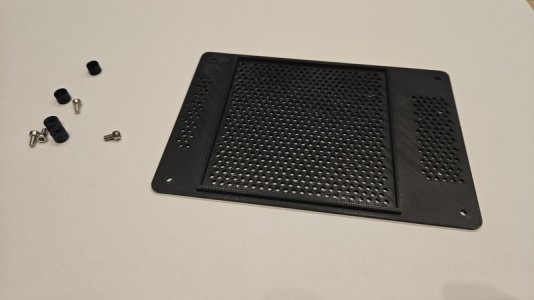

would be worried of dust settling on the internals with such large holes Mike.New project started today.

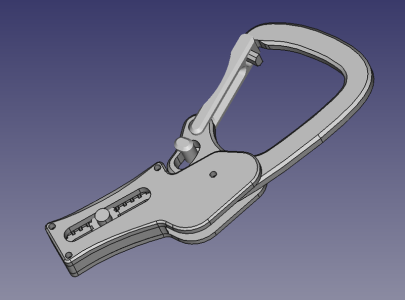

I'm going to replace my home server with a solid state solution.

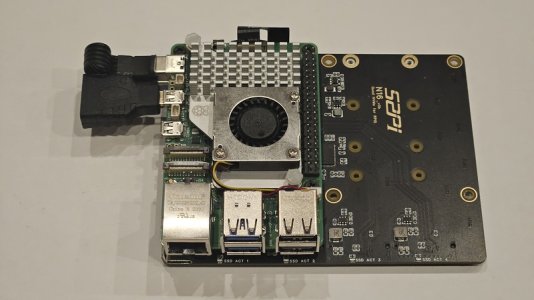

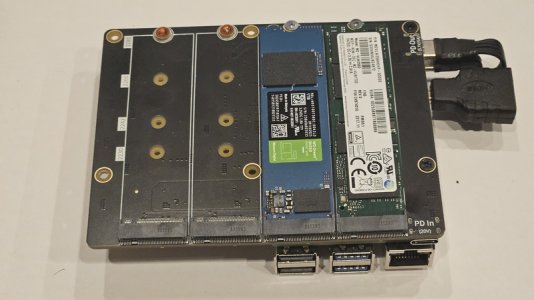

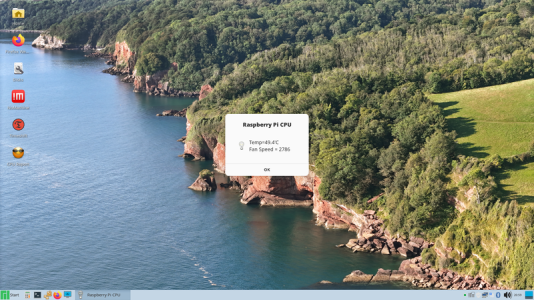

Involving a Raspberry Pi 5 and an addon card carrying 4 NVMe SSDs.

Once I've got it all working, I will be making a suitable enclosure.

This is the hardware

View attachment 181218

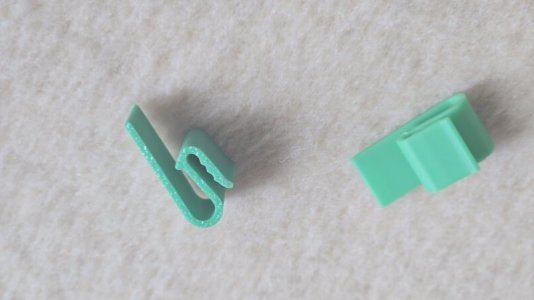

Whilst waiting for the components, I've been experimenting making some ventilation grilles/holes that will be built into the top and base of the enclosure.

Two different grid/grille options currently being printed - see this link

stl 3D viewer

unless you have the hole's panels vertically and force vent it somehow. Else you'll have to remember to remove and air pressure the thing once a year or so (at least down here with lots of dry weather and dust around)