sailygirl

New member

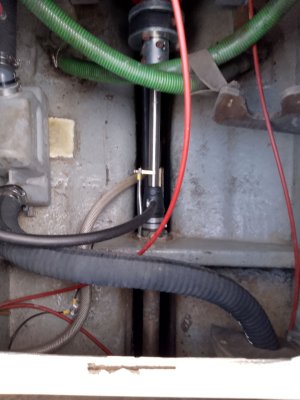

I had a pss seal with a water feed, fail yesterday. This was fitted professionally, just over a year. I was told by the engineer that it did not need squeezing and didnt need to do anything with it. The engineer attending breifly yesterday said that the ceramic seal showed signs of getting hot. I am going to have to fit a new one. Has anyone had a similar problem. Should I be still be squeezing the seal despite the water tube being fitted? Thanks in advance