Ship's Cat 73

Member

Have a Volvo MD5A and there is no fuel getting from the pressure injection pump to the injector.

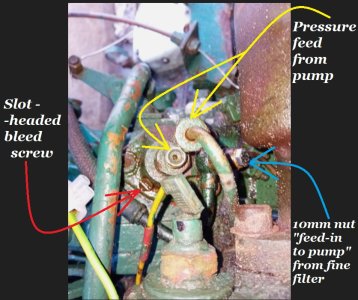

Fuel is present through the fine filter and to the injection pump -- fuel flows freely from the bleed screw at the filter and floods out of the 10mm nut at the pump but nothing gets to the injector, and I mean not as much as a single drip. (YES -- that screw and nut have been tightened when testing for fuel at the injector.)

I'm pretty much a "diesel virgin" but have to assume there is a problem at the pump???

Do these pumps fail, or have problems that I don't know about - - - and what can I be looking for?

. . . and finally, is it possible that some kind of blockage could cause this?

I did exactly as instructed in the online manual to test for air at the pressure pipe at the injector by slackening the large nut and turning the engine.

The nut is arrowed in the photo. (The 'white stuff' in the photo is just some kitchen roll placed there hoping to catch some diesel.)

.

Fuel is present through the fine filter and to the injection pump -- fuel flows freely from the bleed screw at the filter and floods out of the 10mm nut at the pump but nothing gets to the injector, and I mean not as much as a single drip. (YES -- that screw and nut have been tightened when testing for fuel at the injector.)

I'm pretty much a "diesel virgin" but have to assume there is a problem at the pump???

Do these pumps fail, or have problems that I don't know about - - - and what can I be looking for?

. . . and finally, is it possible that some kind of blockage could cause this?

I did exactly as instructed in the online manual to test for air at the pressure pipe at the injector by slackening the large nut and turning the engine.

The nut is arrowed in the photo. (The 'white stuff' in the photo is just some kitchen roll placed there hoping to catch some diesel.)

.