Refueler

Well-known member

One of my pontoons is made up from blue 200L plastic barrels strapped in two lines of 4 under a wood frame / decking. Its a commercial design produced by Jelgava Yacht Club ...

They were adamant that winter and ice would be no problem ... first winter - I pulled it up the bank ... but previous and this last winter I left in ... and those plastic straps have snapped ... barrels still under decking of course as frame holds them in ....

I now have to look at having the pontoon lifted and turned over so I can re-strap the barrels. It will actually give me opportunity to add more barrels as I want to put my self powered mini excavator on it to dig the channel ..

The pontoon as is can take the weight ok ... excavator is 450kg .... but I need to make all stable as the bucket / arm works.

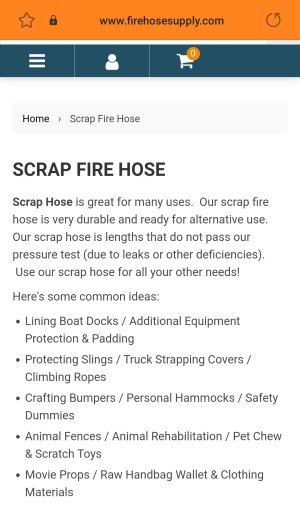

Question is what is better than that plastic strapping ... its basically same as whats used to strap up large boxes / parcels ...

They were adamant that winter and ice would be no problem ... first winter - I pulled it up the bank ... but previous and this last winter I left in ... and those plastic straps have snapped ... barrels still under decking of course as frame holds them in ....

I now have to look at having the pontoon lifted and turned over so I can re-strap the barrels. It will actually give me opportunity to add more barrels as I want to put my self powered mini excavator on it to dig the channel ..

The pontoon as is can take the weight ok ... excavator is 450kg .... but I need to make all stable as the bucket / arm works.

Question is what is better than that plastic strapping ... its basically same as whats used to strap up large boxes / parcels ...