Martin_J

Well-Known Member

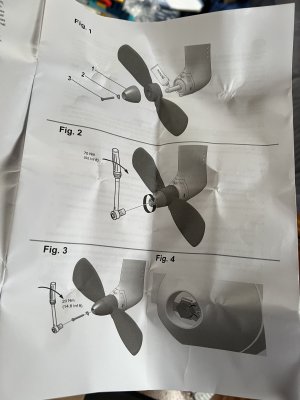

The original post is about a Volvo saildrive.I have a castellated nut & split pin - supplied when I fitted a new shaft & prop after fitting a new engine.

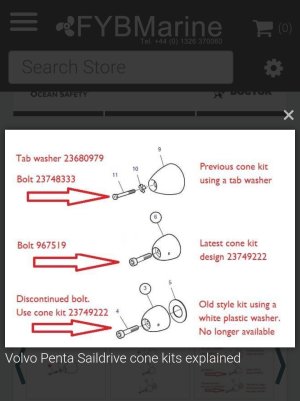

Is your castellated nut on a Volvo saildrive shaft? If so, which model...