winch2

Active member

Morning everyone, we have what I think is a bit of an issue with our setup.

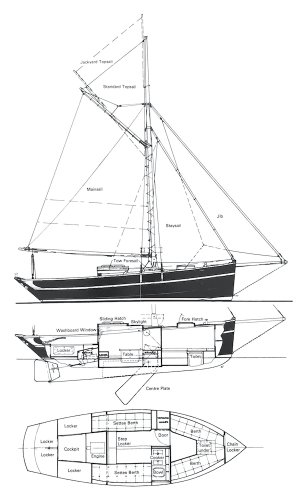

Hauling the peak halyard from the cockpit on our little Crabber is incredibly hard until we get it to about 30 deg then of course it begins to ease. The throat halyard however is wonderfully light and free throughout its travel.

Impression Im getting is that all the Cornish boats have a one purchase arrangement for the peak and a two purchase setup for the throat.. which for my thinking seems the wrong way round as all the weight is taken by the peak when the yard is horizontal. Even pulling it down at the mast, its not much better.

Looking at the many old diagrams of various Gaffs on t'internet and many do seem to have at the least a two purchase arrangement for the peak, some even a three block setup.

I'd really like to add another block for next season but my scientist and methodical other half says nope.."Cornish Crabbers have done the maths and the testing and there's no need".

So do I fit another block or leave it and struggle like mad every time we go sailing?

Im stuck.

Muchos.

Hauling the peak halyard from the cockpit on our little Crabber is incredibly hard until we get it to about 30 deg then of course it begins to ease. The throat halyard however is wonderfully light and free throughout its travel.

Impression Im getting is that all the Cornish boats have a one purchase arrangement for the peak and a two purchase setup for the throat.. which for my thinking seems the wrong way round as all the weight is taken by the peak when the yard is horizontal. Even pulling it down at the mast, its not much better.

Looking at the many old diagrams of various Gaffs on t'internet and many do seem to have at the least a two purchase arrangement for the peak, some even a three block setup.

I'd really like to add another block for next season but my scientist and methodical other half says nope.."Cornish Crabbers have done the maths and the testing and there's no need".

So do I fit another block or leave it and struggle like mad every time we go sailing?

Im stuck.

Muchos.

Last edited: