Roughcut

Member

They’re DPG legs - stainless props and yes they have the old-style impressed current system. 2 units on each side. The lights blink at roughly the correct rate as far as I can tell but I have no idea if they really work. Do they ever wear out? Or need refurbishing?

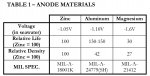

I did see something about VP and Aluminium anodes - but it didn’t seem to make any sense to me either. I don’t see how AL protects AL drives. I definitely have zinc ones at the moment. Sounds like I’d better lay in a store of them…

I did see something about VP and Aluminium anodes - but it didn’t seem to make any sense to me either. I don’t see how AL protects AL drives. I definitely have zinc ones at the moment. Sounds like I’d better lay in a store of them…