Refueler

Well-known member

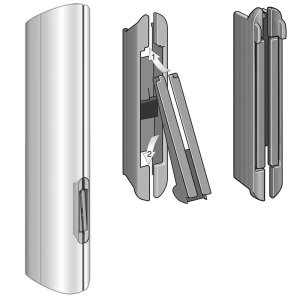

Trying to remove mainsail from my 38 .... the gate is the long version that caters for both normal and batten sliders ....

Cannot get it to open ... any suggestions ?

(My other boat has the simple Proctor system of a thuimb screw and plate....)

Cannot get it to open ... any suggestions ?

(My other boat has the simple Proctor system of a thuimb screw and plate....)