You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air pockets coming from stuffing box

- Thread starter Karlsenkystfiske

- Start date

ean_p

Well-known member

Isn't the bubble travelling up the line to the stern gland.....? In which case its just an air bubble in a poorly filled greaser. Is it grease or oil or indeed a slurry of the two? To establish which way its moving just mark on the hose the leading edge of the bubble with a pen......I would be surprised if it is being driven up into your reservoir rather than down into your gland if its grease......

Karlsenkystfiske

Member

Done! I imagined I had been thorough when packing the greaser. But we will see

Aja

Well-known member

Did mine yesterday. Its a messy job and really quite difficult to pack the grease into the greaser. It would be difficult to pack without getting air in the mix. Just ignore the air bubbles.Done! I imagined I had been thorough when packing the greaser. But we will see

Karlsenkystfiske

Member

Aaand you were right! The air pockets are moving downwards

Dont realy like this lubrication system. Messy to refill, and obviously a bit difficult to fill the cups properly! Maybe I should look into some auto cartridge solution...

Dont realy like this lubrication system. Messy to refill, and obviously a bit difficult to fill the cups properly! Maybe I should look into some auto cartridge solution...

ean_p

Well-known member

Don't waste your money.......the odd air bubble won't do anything much so long as they keep moving.....you just need a little more care when topping it up, but don't sweat over it.....auto lube (slurry) systems are notoriously fickle.......Aaand you were right! The air pockets are moving downwards

Dont realy like this lubrication system. Messy to refill, and obviously a bit difficult to fill the cups properly! Maybe I should look into some auto cartridge solution...

Chiara’s slave

Well-known member

The headline sounded rather rude. I’m disappointed by the content.

Tranona

Well-known member

If you don't like it change the seal for something more modern. The grease does not lubricate anything. It is there to reduce the flow of water up the stern tube so that when the boat is at rest the packing does not drip. The packing is self lubrication. You have to regularly replace it as it gets washed away when running hence the normal routine of giving the handle a couple of turns when you leave the boat. A modern drip free seal does not need this.Aaand you were right! The air pockets are moving downwards

Dont realy like this lubrication system. Messy to refill, and obviously a bit difficult to fill the cups properly! Maybe I should look into some auto cartridge solution...

However that is a very tight installation and you may not be able to change it.

ean_p

Well-known member

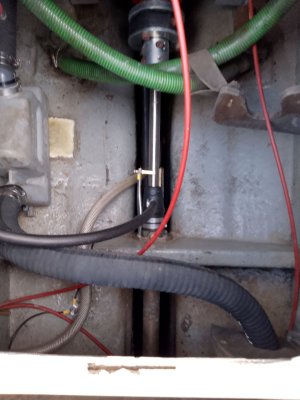

Having another quick look at your photos.....are you certain you have a stuffing gland seal and not some form of mechanical seal housed in the brass item protruding from the hose. I don't see any follower / gland nut assembly associatedwith the brass item..?

Karlsenkystfiske

Member

Aie-aie sir! i will let it go. I am starting to get concerned about greasing of the shaft seal though. For a couple of months now the greaser have felt hard. Can it be that I have greased too much and the stuff have hardened in there?

Tranona

Well-known member

Difficult to say without knowing the construction of the box and the type of seal used. My comments assume it is a conventional packed gland, but like ean-p I now have my doubts because it does not look like it has the usual adjustment. It is not clear where the grease tube enters or exactly where the internal seal is located.

Supertramp

Well-known member

There is very soft (air pocket), medium (pumping grease, no back pressure) or hard (pumping grease and the bearing is full creating back pressure). As soon as the shaft rotates the back pressure drops. Based on dismantling mine after 4 years, the grease doesn't harden.Aie-aie sir! i will let it go. I am starting to get concerned about greasing of the shaft seal though. For a couple of months now the greaser have felt hard. Can it be that I have greased too much and the stuff have hardened in there?

A good point. I have always added a turn every hour when motoring, and then about 2 turns at rest to stop drips. On dismantling recently I had masses of grease along the 4 foot stern tube creating the risk of bunging up the cutlass. I will be using fewer turns less frequently from now on. I don't mind the drips from the conventional gland - it's reassuring to know the bilge pump works!If you don't like it change the seal for something more modern. The grease does not lubricate anything. It is there to reduce the flow of water up the stern tube so that when the boat is at rest the packing does not drip. The packing is self lubrication. You have to regularly replace it as it gets washed away when running hence the normal routine of giving the handle a couple of turns when you leave the boat. A modern drip free seal does not need this.

However that is a very tight installation and you may not be able to change it.

Tranona

Well-known member

Much nicer to have a simple neat, cheap non drip solution like this! The tube is a vent and the shiny metal bit an Electroliminator connecting the hull anode to the shaft/propThere is very soft (air pocket), medium (pumping grease, no back pressure) or hard (pumping grease and the bearing is full creating back pressure). As soon as the shaft rotates the back pressure drops. Based on dismantling mine after 4 years, the grease doesn't harden.

A good point. I have always added a turn every hour when motoring, and then about 2 turns at rest to stop drips. On dismantling recently I had masses of grease along the 4 foot stern tube creating the risk of bunging up the cutlass. I will be using fewer turns less frequently from now on. I don't mind the drips from the conventional gland - it's reassuring to know the bilge pump works!

Attachments

Boater Sam

Well-known member

It is not messy filling a greaser if you know how to do it. And doing it properly you do not get air bubbles.

Last edited:

Supertramp

Well-known member

That is very neat and I can see the appeal.Much nicer to have a simple neat, cheap non drip solution like this! The tube is a vent and the shiny metal bit an Electroliminator connecting the hull anode to the shaft/prop

I have an enormous deep sump under the propshaft so a bit of water is not a worry. And the grease not messy as it goes down the shaft, not into the boat. I will consider one next time I take the shaft out.

Karlsenkystfiske

Member

Could you offer up some guidance?It is not messy filling a greaser if you know how to do it. And doing it properly you do not get air bubbles.

Supertramp

Well-known member

Mine unscrews at the base. I then wind the plunger back out a bit to create a dip in the exposed grease surface and fill using a knife blade. Then wind the plunger some more and repeat until the fill is completed. Reassemble with the grease a little proud of the surface so no air traps as I screw it on.

Your system is different but should follow a similar principle. What is very different is the diameter and material of your grease line to the gland - mine is short, thin and hard plastic (about 4mm). So an air bubble pumps through quick. And your grease looks black where I use white lithium grease.

Your system is different but should follow a similar principle. What is very different is the diameter and material of your grease line to the gland - mine is short, thin and hard plastic (about 4mm). So an air bubble pumps through quick. And your grease looks black where I use white lithium grease.

Refueler

Well-known member

Could you offer up some guidance?

If its the standard barrel type with threaded plunger .... unscrew the barrel from the base plate. Wind the threaded plunger all way down (may have to catch any remaining grease and 'spoon' it back in ....

Take pot of grease - hopefully with the plate and hole in centre on top of the grease ... place barrel over hole in plate ... press lightly while unscrewing threaded plunger - this should create suction pulling solid grease into the barrel.

There should be no need to use a blade or spoon to fill the barrel ... its same action as used for filling standard grease guns.

In use ? Before starting any trip - I give greaser a couple of turns on the plunger - just to get a small amount of fresh grease in to the seal. I then go on my trip ... I don't give any more grease during the run ... the slight ingress of water provides the necessary .... along with the packing.

Once arrived at destination and engine stopped - I then give a couple of turns again.

I used to give turns every few hours during a trip - but ended up with grease spread around the bilge where too much excess was thrown out at the adjustment nut ...

Strangely I also noted that packing tended to be scorched when replaced - which may have been due to too much grease preventing water from getting to the packing. Since changing to not greasing during trips - I noticed last change of packing - it was not scorched.

NormanS

Well-known member

Ideally, packing should be adjusted so that when the shaft is rotating, an occasional drip comes in. This ensures that the packing is being sufficiently lubricated by the water.

A standard packing gland doesn't need to have grease pumped into it during normal use. All you're doing is filling the stern tube. It is, however, good practice to pump in a little at the end of a cruise, if intending to leave the boat unused for a while. This prevents an occasional drip.

A standard packing gland doesn't need to have grease pumped into it during normal use. All you're doing is filling the stern tube. It is, however, good practice to pump in a little at the end of a cruise, if intending to leave the boat unused for a while. This prevents an occasional drip.

Karlsenkystfiske

Member

These ones are just "threaded pots". Greased are pushed down the hose when you screw it downwards. No plunger.

Other threads that may be of interest

- Replies

- 1

- Views

- 99

- Replies

- 123

- Views

- 3K