Stewbabe

New member

Hi Guys whats the best synthetic teak decking out of Permateek and Flexiteek !! Anyone had any problems !! It would be for a 28 ft sportsboat cockpit and bathing platform !! What about warranty !! Thanks Guys

Tek-Dek were a piece cheaper than that, our link below has quite a few photos of their work.Thanks guys Permateek want £500 per square metre all in fitted !! I am going to measure but I think I need about four square metres !!

@Hurricane - huge respect and admiration for what you have done on JW!

Just looked at your install pics. It looks 1st class! Great work..We had Permateek fitted to our Squadron 58 and were very pleased with it, we loved the colour and being in the UK the fact that on a sunny day it was hotter to the touch than real wood was rarely an issue (sadly!). Synthetic decks make maintenance very easy as you can just pressure wash them down when they get grubby. Real teak does have benefits of course but there is a cost differential too. You can see what mine looked like and what the process was here:

Squadron 58 Replacement Decks

I like your router jig. How did you radius the curves for the board and the perspex block?Right now, I into my next phase of teak replacement (Trakmark).

This time its the cockpit.

Here is a photo of the progress so far - only just fits in my garage.

View attachment 171567

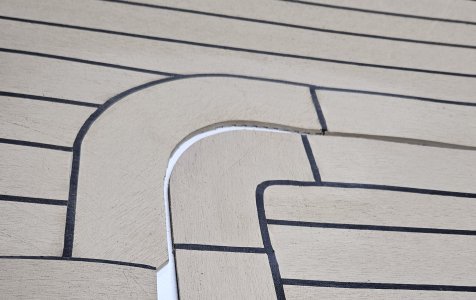

I am working on a new (to me) technique to make curved corners.

View attachment 171568

Seems to work - this is the hatch for the lazerette

View attachment 171569

Although I say it myself, I'm much better at welding than when I started. I think I've even cracked top welding!!

No set jig.I like your router jig. How did you radius the curves for the board and the perspex block?

Thanks. All good thinking …and execution.No set jig.

I have spent a lot of time thinking about borders - even some hairbrained ideas of CNC routing!!

The solution in the end is quite simple.

I cut two perspex discs - exactly 57.25mm radius

I fitted on onto a cheap Palm Router, making sure that the disc was centered.

The other disc has a hole in the center for a pencil.

The process is as follows:-

Draw the profile of one of the edges (I used an old school compass for the round corners).

If it is an inside border/curve, I draw the profile for the outside edge (in this case using a compass)

If it is an outside border/curve, I draw the profile for the inside edge (in this case using a compass)

I hope that makes sense.

After cutting the appropriate edge, I use one of those bendy French curves.

I push the French curve around the previously cut edge and hold it in place with some weights (a good set of weights are vital when making this stuff).

I then use the disc wit a hole in the center to draw the other edge.

And cut it.

That now leaves a border piece that is the exact size.

This pic shows the technique - in the pic, I've already cut the curve.

View attachment 171642

I then glue that border piece into the job.

The reason for all this is that later when the that piece is fitted into the job, I can use the same edge and same French Curve but this time I use the disc that it fitted to the Palm Router.

Like this

View attachment 171643

This leaves a nice groove with smooth edges like this

View attachment 171644

Those straight grooves are made using a standard Plunge Router and a perspex fence.

Trakmark supply a special soft welding rod with a lower melting point for top welds.

Using the same weld tool and nozzle, the weld rod is fed into the groove.

Excess rod is cut off and the job sanded.

Final result

View attachment 171647

Hope that answers the question.

Hi which company are you using and where is your boat! Does that price include preparing the floor/removing old teak! Thanks StewI'm going with Permateak - Not brave enough to measure & fit myself - too expensive to get wrong and too visible if a mistake is made - I'm paying around £2k for 4.8m2. But that includes 2 x 400 mile round trips for the guy to come and measure and then fit on the 2nd visit. I think it will be well worthwhile!