Coldevolution

New member

I have a Volvo 5.7 Gi E that after winterisation suffered a cracked block. Trying to locate a block and getting quoted prices around 10k from Volvo to 1k from GM suppliers doing old Chevy engines.

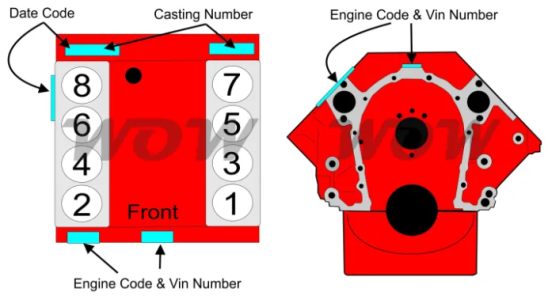

Im being told the Volvo engine uses a Votec 880 block which is a GM block. First trying to find out the casting numbers to see if I can at minimum agree this is the block. Most of these blocks are known as re manufactured which means honing or boring out a few mm... and what that means with the swap over of parts. I see people have repaired these with JB weld material and got good use from the repair... Really not sure what way to approach.

Any thoughts to finding a block to replace if numbers stack up, and any experience on JB weld... considering I believe the water jacket is around 15psi... Heads wrecked... Engine before the problem was purring like a kitten and could see near 50 knots on the Crown 220. Thank you for any advice in advance.

Im being told the Volvo engine uses a Votec 880 block which is a GM block. First trying to find out the casting numbers to see if I can at minimum agree this is the block. Most of these blocks are known as re manufactured which means honing or boring out a few mm... and what that means with the swap over of parts. I see people have repaired these with JB weld material and got good use from the repair... Really not sure what way to approach.

Any thoughts to finding a block to replace if numbers stack up, and any experience on JB weld... considering I believe the water jacket is around 15psi... Heads wrecked... Engine before the problem was purring like a kitten and could see near 50 knots on the Crown 220. Thank you for any advice in advance.