penfold

Well-Known Member

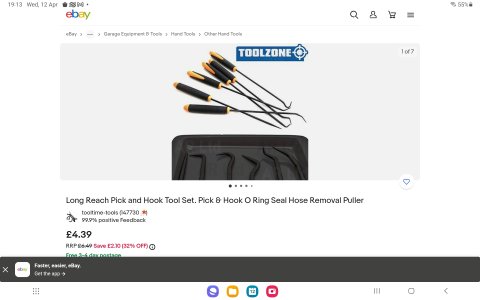

Either a pick set(looks like a mechanics' version of dentist tools) or what amounts to a sort of flexible corkscrew made from varying sizes of curtain rod; the latter can be fitted in a battery drill for maximum excitement.Can anyone tell me how tough it usually is to get the old packing out? I imagine it very firmly packed after years of being compressed.

I've got the job to do, but difficult access. I think I need, ideally, a tool with a sharp screw type end, to cut into the surface and dig out the packing, but also with a narrow, strong, rigid but cranked shaft from an easily gripped (and not dropped!) handle.

I've previously read people suggest something like a corkscrew, or a self-tapping screw secured to the end of a screwdriver with heat shrink, but

a) the packing is just 5mm and the shaft prevents me from getting a proper turning tool (with my hand round it) lined up and into the 5mm gap; and

b) the challenges of my access mean (unless I can find a much smaller volunteer for the job!) I'll be doing it one handed (and over a very deep bilge, upside down and diagonally in the cockpit locker, lying on one arm and some uncomfortable lumps!).