Tranona

Well-known member

There have been a number of recent threads on this subject and I thought I might share what I have done for the coming year.

My Golden Hind had no anodes for the first 40 odd years of its life (except uselessly on the steel bilge plates!) and there was no sign of any galvanic action anywhere. Four Blakes seacocks and one DZR ball valve underwater and a fixed 3 blade propeller on a stainless shaft. I have fitted a new engine and stern gear with a Featherrstream propeller. The latter does need an anode because it is mixed bronze with stainless gears and blades. The boat is only hauled once a year and I was hoping that the anode would last a year. However after 10 months the anode was over half gone and crucially, as often happens with this style had eroded around one of the fixing screws. As that lift (end of July) was primarily to change the propeller pitch I just replaced the anode. Hauled 2 weeks ago and the first photo shows the state of the anode - unlikely to last another year.

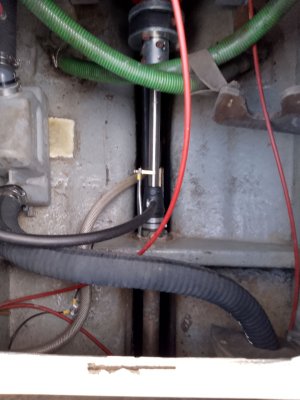

I had already had discussions with Darglow and Mike Wills who installed the engine and stern gear and come to the conclusion that a second hull mounted anode would be useful. The challenge with the hull anode was to get it as close to the propeller as possible given the back end of the hull is full of fuel tanks. The second photo shows what we managed. The next problem was how to wire it to get good consistency of contact with the shaft and therefore the propeller. The most common way is using the gearbox housing bolts, but we have fitted a Bullflex coupling which makes a wire across from the gearbox flange to the output difficult. Decision therefore was to use a shaft brush which was easy to mount on a studded bar through the mounting bolt for the inner end of the stern tube. See third photo.

I had left the prop bare hoping that it would keep clean enough but at the first liftout I was surprised at barnacles and tube worm on the blades. I am also aware that there is some support for painting propellers to reduce the surface area exposed to salt water as a way of slowing galvanic action. I have previously used Velox on propeller blades but was concerned about whether it would stick to stainless, so decided to give Hempel Ecopower which I have also used previously a try. Last 2 sinister looking photos show the result - hope it will also scare the barnacles away.

Back in the water today but obviously won't know if it is all worth it until next year.

My Golden Hind had no anodes for the first 40 odd years of its life (except uselessly on the steel bilge plates!) and there was no sign of any galvanic action anywhere. Four Blakes seacocks and one DZR ball valve underwater and a fixed 3 blade propeller on a stainless shaft. I have fitted a new engine and stern gear with a Featherrstream propeller. The latter does need an anode because it is mixed bronze with stainless gears and blades. The boat is only hauled once a year and I was hoping that the anode would last a year. However after 10 months the anode was over half gone and crucially, as often happens with this style had eroded around one of the fixing screws. As that lift (end of July) was primarily to change the propeller pitch I just replaced the anode. Hauled 2 weeks ago and the first photo shows the state of the anode - unlikely to last another year.

I had already had discussions with Darglow and Mike Wills who installed the engine and stern gear and come to the conclusion that a second hull mounted anode would be useful. The challenge with the hull anode was to get it as close to the propeller as possible given the back end of the hull is full of fuel tanks. The second photo shows what we managed. The next problem was how to wire it to get good consistency of contact with the shaft and therefore the propeller. The most common way is using the gearbox housing bolts, but we have fitted a Bullflex coupling which makes a wire across from the gearbox flange to the output difficult. Decision therefore was to use a shaft brush which was easy to mount on a studded bar through the mounting bolt for the inner end of the stern tube. See third photo.

I had left the prop bare hoping that it would keep clean enough but at the first liftout I was surprised at barnacles and tube worm on the blades. I am also aware that there is some support for painting propellers to reduce the surface area exposed to salt water as a way of slowing galvanic action. I have previously used Velox on propeller blades but was concerned about whether it would stick to stainless, so decided to give Hempel Ecopower which I have also used previously a try. Last 2 sinister looking photos show the result - hope it will also scare the barnacles away.

Back in the water today but obviously won't know if it is all worth it until next year.