pragmatist

Well-known member

Sorry - yes me again. Just posted on varnish but we're onto the winter list so here's the next one !

Having had our 36' catamaran for a couple of years we have decided that we would like two new goodies - a full cockpit cover to give us more space and to keep out the British weather - and we would like to increase the number of solar panels. We already have solar panels on the coach-roof - its either a hard top or an arch and the former would fulfill both the objectives.

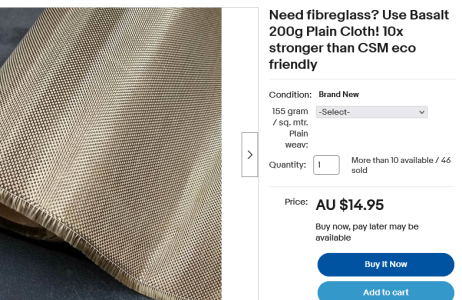

So the idea is to commission someone to make and fit a hard top which fits to the existing windscreen, covers part of the cockpit including the helmsman's seat & instruments, allows us to site some more solar and then to add to this a canvas cockpit cover with lots of windows. Don't say make it yourselves - as has been suggested elsewhere on this forum - our skill levels and patience aren't up to it ! We're thinking something like fibre-glass with high density foam. It doesn't need to be too strong as there is no need to walk about on it - just to support a couple of big solar panels and provide the attachment for the canvas cover. Beyond the windscreen there is currently no support for a hard top or cover so we'd be looking at either fibreglass supports or stainless.

Given that its not totally straightforward it is likely that we will need someone to measure and design, as well as to fabricate and fit. We're based on the River Dart. Does anyone know or have experience of a similar project ? And can anyone recommend someone (probably reasonably local) to do the job ? TIA.

Having had our 36' catamaran for a couple of years we have decided that we would like two new goodies - a full cockpit cover to give us more space and to keep out the British weather - and we would like to increase the number of solar panels. We already have solar panels on the coach-roof - its either a hard top or an arch and the former would fulfill both the objectives.

So the idea is to commission someone to make and fit a hard top which fits to the existing windscreen, covers part of the cockpit including the helmsman's seat & instruments, allows us to site some more solar and then to add to this a canvas cockpit cover with lots of windows. Don't say make it yourselves - as has been suggested elsewhere on this forum - our skill levels and patience aren't up to it ! We're thinking something like fibre-glass with high density foam. It doesn't need to be too strong as there is no need to walk about on it - just to support a couple of big solar panels and provide the attachment for the canvas cover. Beyond the windscreen there is currently no support for a hard top or cover so we'd be looking at either fibreglass supports or stainless.

Given that its not totally straightforward it is likely that we will need someone to measure and design, as well as to fabricate and fit. We're based on the River Dart. Does anyone know or have experience of a similar project ? And can anyone recommend someone (probably reasonably local) to do the job ? TIA.