PabloPicasso

Well-Known Member

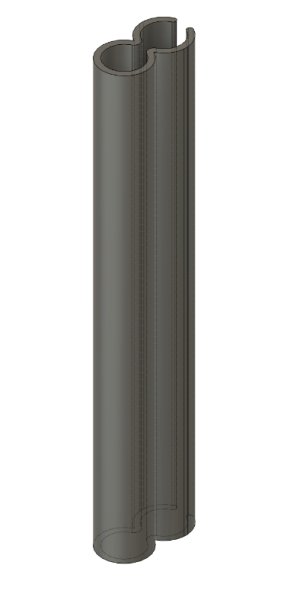

How does one replace the wire inside a forestay furler?

Once the mast is down and stays removed from the mast, is it easy to slide the wire out, and a new one back in?

How is it connected to the end fitting, does it need to be hydaulically pressed in?

Can I DIY, or do I need to hire a pro?

Once the mast is down and stays removed from the mast, is it easy to slide the wire out, and a new one back in?

How is it connected to the end fitting, does it need to be hydaulically pressed in?

Can I DIY, or do I need to hire a pro?