Mr Splat

New member

Hi guys,

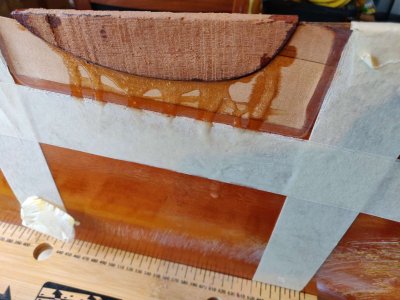

I was recently out in my Phantom dinghy in blustery conditions and in the process of a dry capsize it appears that I have stood on the trailing edge of my wooden centerboard and a piece has splintered off it

I have little knowledge of repairing foils but from asking around the accepted wisdom appears to be to grind out the highlighted section (which is where I can see signs of damage) and rebuild it using epoxy.

The trailing edge is very thin so I'm thinking it would be necessary to go quite far back into the wood so that the epoxy has something to bond to, I would also need something to keep the epoxy in place while it cures, maybe a pair of steel rules and some clamps, or maybe glass fibre tape?

Once cured I would have to sand the epoxy back and finish it and any of the affected wood which would probably require two pack varnish?

I'm having a little bit of trouble finding guides to doing such repairs, possibility approaching this as a novice, would anyone be able to provide some pointers to good guides or even just provide some pointers as to how they would approach such a repair?

I was recently out in my Phantom dinghy in blustery conditions and in the process of a dry capsize it appears that I have stood on the trailing edge of my wooden centerboard and a piece has splintered off it

I have little knowledge of repairing foils but from asking around the accepted wisdom appears to be to grind out the highlighted section (which is where I can see signs of damage) and rebuild it using epoxy.

The trailing edge is very thin so I'm thinking it would be necessary to go quite far back into the wood so that the epoxy has something to bond to, I would also need something to keep the epoxy in place while it cures, maybe a pair of steel rules and some clamps, or maybe glass fibre tape?

Once cured I would have to sand the epoxy back and finish it and any of the affected wood which would probably require two pack varnish?

I'm having a little bit of trouble finding guides to doing such repairs, possibility approaching this as a novice, would anyone be able to provide some pointers to good guides or even just provide some pointers as to how they would approach such a repair?