KompetentKrew

Well-Known Member

Can a stainless steel turnbuckle like this seize, please?

It's only 4½ years old.

I have to inspect and, no doubt, replace my chainplates - I want to do the longest one first because that seems to be the most complex. It seems to be a stainless steel tube with a length of SS bar welded at each end, but I'll post pics of that once I've removed it - its stay is quite taught, so I wanted to ease the tension before removing all the bolts, but was unable to do so.

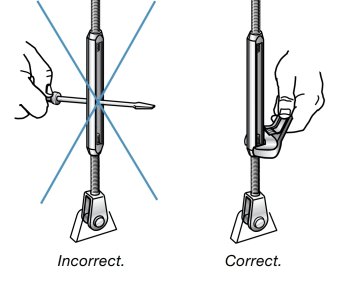

It's the top section of the turnbuckle which seems seized - I had a spanner on the wrench flat indicated on the second pic and then tried putting a second spanner though the turnbuckle's hole in order to use that as a lever, but it wouldn't budge at all. I was almost afraid I might break the spanner!

I had assumed these would turn relatively easily.

I poured a couple of kettles full of boiling water over it, applied some 3-in-1 oil and have left it overnight. I would appreciate any advice.

It's only 4½ years old.

I have to inspect and, no doubt, replace my chainplates - I want to do the longest one first because that seems to be the most complex. It seems to be a stainless steel tube with a length of SS bar welded at each end, but I'll post pics of that once I've removed it - its stay is quite taught, so I wanted to ease the tension before removing all the bolts, but was unable to do so.

It's the top section of the turnbuckle which seems seized - I had a spanner on the wrench flat indicated on the second pic and then tried putting a second spanner though the turnbuckle's hole in order to use that as a lever, but it wouldn't budge at all. I was almost afraid I might break the spanner!

I had assumed these would turn relatively easily.

I poured a couple of kettles full of boiling water over it, applied some 3-in-1 oil and have left it overnight. I would appreciate any advice.