Boathook

Well-Known Member

I think not. I wouldnt call duralac a lubricant.I think I have some duralc somewhere. Would that do the same job as tef-gel?

I think not. I wouldnt call duralac a lubricant.I think I have some duralc somewhere. Would that do the same job as tef-gel?

The stuff is a bit dear. The Locktite product is much cheaper and as good.I was recommended to use Tefgel by a rigger a few years ago. Having purchased it, I could then understand why he wouldn't leave me some.

Well yeh.I was recommended to use Tefgel by a rigger a few years ago. Having purchased it, I could then understand why he wouldnt leave me some.

I've never used PTFE tape as a lubricant. Only ever used it to seal gas and water joints. I've never used PE bags either for such applications.Well yeh.

OTOH, PTFE tape is cheap and pretty much guaranteed to last forever in the thread interface, though it isnt absolutely guaranteed to prevent corrosion.

Polythene sheet (from a suitable plastic bag) is free, but otherwise ditto.

I havn't done any controlled comparative tests, but I'd think that, in combination with a lesser grease or antiseize, it might compare quite well, though I''ve so far only used this approach on cars and motorcycles.

(Of course if you are hung up on torque values (I'm not) you wont be able to allow yourself to use anything, and your fastners are accordingly doomed)

Everybody sailing boat has some duralac somewhere. In most cases, it's turned to stoneI think I have some duralc somewhere. Would that do the same job as tef-gel?

So what?I've never used PTFE tape as a lubricant. Only ever used it to seal gas and water joints. I've never used PE bags either for such applications.

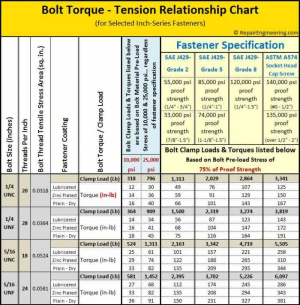

IME, bolts that require accurate torque setting are normally lubricated, since the clamp tension achieved with dry tightening is more variable, and unless you degreased the bolts, there is probably some oil there. This chart is for engine oil; some lubes will reduce the torque even farther, perhaps 10-15%.... (Of course if you are hung up on torque values (I'm not) you wont be able to allow yourself to use anything, and your fastners are accordingly doomed)

IIRC torque values are very often quoted "dry", and are assumed to be "dry" unless otherwise stated, but "dry" may in fact mean lightly oiled, though this is seldom stated and IMO is counterintuitive to the point of being nonsensical.IME, bolts that require accurate torque setting are normally lubricated, since the clamp tension achieved with dry tightening is more variable, and unless you degreased the bolts, there is probably some oil there. This chart is for engine oil; some lubes will reduce the torque even farther, perhaps 10-15%.

View attachment 204108

| Lubricant | Torque Reduction (%) |

|---|---|

| Graphite | 50 - 55 |

| White Grease | 35 - 45 |

| SAE 30 oil | 35 - 45 |

| SAE 40 oil | 30 - 40 |

Yes, sometimes confusing. Except for galvanized, which are non-lubed as delivered, machined bolts generally will have thread cutting lube, so I always go lube and go with that figure. When in doubt, you can always look at SAE or equivalent tables.T The goal is to pre-stretch the bolt to close to its working load limit, so that the tension does not cycle in use.IIRC torque values are very often quoted "dry", and are assumed to be "dry" unless otherwise stated, but "dry" may in fact mean lightly oiled, though this is seldom stated and IMO is counterintuitive to the point of being nonsensical.

"even further, perhaps 10-15%" sounds rather low. For example

Lubricated Bolts and Reduced Torque

Lubricant Torque Reduction

(%)Graphite 50 - 55 White Grease 35 - 45 SAE 30 oil 35 - 45 SAE 40 oil 30 - 40

I concluded long ago that torque values are mostly bollocks, dont usually bother with a torque wrench, and hardly ever use a dry fastner, though I have sometimes used the "turn of the nut" method to "translate" dry torque values into an angular value that should be the same for a lubricated fastner.

This doesnt seem to really work very well for head bolts because they interact, and the gasket compresses further on re-torqueing.

"perhaps another 10-15%" would indeed have been clearer.Yes, sometimes confusing. Except for galvanized, which are non-lubed as delivered, machined bolts generally will have thread cutting lube, so I always go lube and go with that figure. When in doubt, you can always look at SAE or equivalent tables.T The goal is to pre-stretch the bolt to close to its working load limit, so that the tension does not cycle in use.

I said that some lubes reduce the torque further than engine oil. perhaps another 10-15%. 10-15% plus 35-45% equals the 50-55% for graphite, so my statement was correct.

The odds of galling stainless by torquing dry are so great that I would always avoid it. In fact, most of the bolts have some oil on them if you did not de-grease them. But you don't know; sometimes you'll get away with it, if only a fraction of a turn until tight, but if the bolt is truly dry and you draw it up quickly, many turns, under load, the odds are against you. If you can feel ANY heat in the nut, you probably blew it, at least in part.