Tranona

Well-Known Member

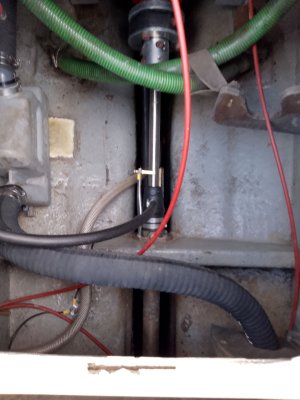

I think you will find he agrees with me and that bonding (in the US) is primarily for lightening protection. It is a "fashion" for some builders, particularly of motor boats to bond all underwater metal fittings but there is no logical or scientific reason to do so. There are specific fittings that meet the conditions where a galvanic cell could form and an anode could be needed. The most common are yellow metal props and stainless shafts, mixed metal rudders, usually yellow metal and stainless, bow thrusters, aluminium and stainless, saildrives/outdrives, aluminium and stainless. In all cases these are mixed metals of different potential in contact in an electrolyte (seawater). A seacock does not have these properties, being a single metal in contact with GRP. One caveat, most ball valves do have mixed metals such as operating shafts of steel but they are not actually in contact in water, nor would an anode be of any use if they were because the anode has to be close to the item in line of sight. The latter condition is another reason why bonding to an anode would not be effective as most bonding circuits have anodes that are remote from seacocks. The photos show the hull anode protecting the stern gear on my boat. As you can see it is close to the propeller - recommendation is less than a metre and bonded to the shaft through a brush on the shaft inside. This is in addition to an anode on the prop which goes first because it is closer. None of the 5 seacocks have anodes and have been there since 1979.Interesting as my Boat has from factory all of the seacocks bonded.. I shall consult with Nigel Calder again and see his take on seacock bonding..