lustyd

Well-Known Member

Looks like 25 years of neglect and fenders rubbing off the UV protection. That’s not a design issue it’s negligence from owners.From the post by @noelex .... not the factory finish .... wonder what the history of the windows is?

View attachment 204622

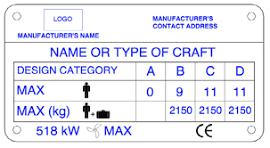

View attachment 204623