billskip

Well-Known Member

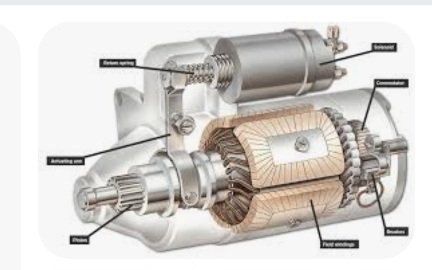

The fork that is moved by the solenoid slides the pinion gear on the starter motor rotor shaft ..into the engine flywheel ring gear. The starter motor rotor shaft has very little end thrust movement.There is no mechanism to 'ram a pinion into the ring gear'. The pinion is firmly attached to the motor rotor. The whole rotor needs to move, energised by the solenoid, before engagement can occur. Totally different from a Bendix gear, which was used successfully for almost 50 years