CJ13

Active member

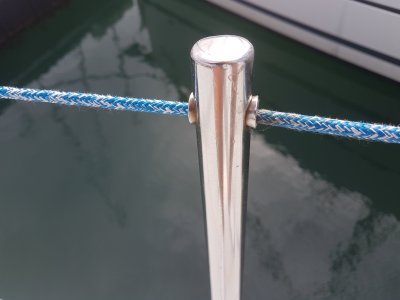

Following my earlier post I’m going to replace my plastic coated wire guard rail lines with 6mm dyneema.

The lines run thro holes in the stanchions and we tie fenders onto them.

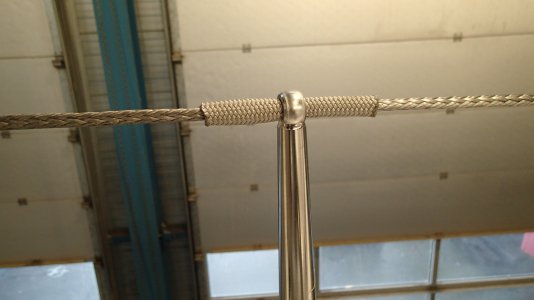

For chafe protection where they run thro the stanchions I can either use split plastic tube, which has the advantage of being fairly rigid, so easy to tie fender to, or Dyneema Chafe Sleeves, which are soft so I suspect less easy to tie to?

Has anyone experience of either option or another solution?

The lines run thro holes in the stanchions and we tie fenders onto them.

For chafe protection where they run thro the stanchions I can either use split plastic tube, which has the advantage of being fairly rigid, so easy to tie fender to, or Dyneema Chafe Sleeves, which are soft so I suspect less easy to tie to?

Has anyone experience of either option or another solution?