Hoist

Well-Known Member

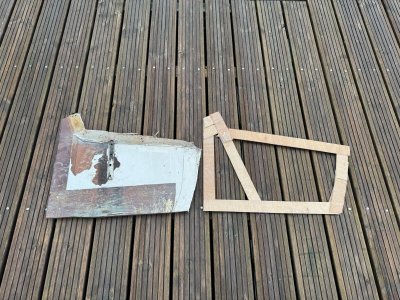

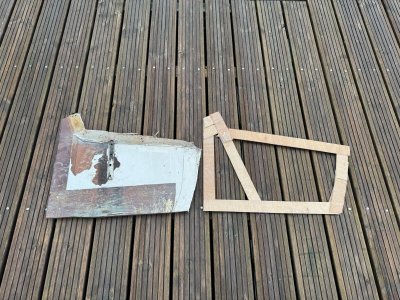

Attacked the Starboard Main bulkhead this afternoon. The jigsaw and grinder quickly relieved it!

The water damage was the same on this side. The wood was able to come out whole but as you can see it was very close to failure also.

Got the template all made up and so I'll be ready to cut out the new bulkhead tomorrow

One thing I have noticed on this side is that the tabbing was a lot stronger. The access is much easier than the port side and they seem to have made a much better job of it on day 1. I did consider using the old piece of wood instead of templating, however by using the template I am able to get a much better fit and the resulting bulkhead will be much stronger than the original. Just for reference the original bulkhead had a gap where the tabbing was pushed in between of around 1" on the outside face. The only part that was butted up to the deck was the section directly under the deck

The water damage was the same on this side. The wood was able to come out whole but as you can see it was very close to failure also.

Got the template all made up and so I'll be ready to cut out the new bulkhead tomorrow

One thing I have noticed on this side is that the tabbing was a lot stronger. The access is much easier than the port side and they seem to have made a much better job of it on day 1. I did consider using the old piece of wood instead of templating, however by using the template I am able to get a much better fit and the resulting bulkhead will be much stronger than the original. Just for reference the original bulkhead had a gap where the tabbing was pushed in between of around 1" on the outside face. The only part that was butted up to the deck was the section directly under the deck