Hunterlees

Well-Known Member

Try a soldering iron onto the head of each screw.

[p.s. Hunterlees types faster than me!]

…. but can't always be used because of the space needed around the nut/bolt head to accommodate the thicker than standard ring of the spanner.

Is there enough metal protruding for these to grip? They come in a wide range of sizes and I've found them very effective. https://amzn.eu/d/hz7lZTb

They do do a set designed for screws, if you look at the Irwin Amazon shop.Neat, but I suspect the heads are too small. The depth of the head (of an undamaged screw) is 3.5mm but the diameter is only 6.4mm and the smallest tool in your link is for 8mm. Thanks for the suggestion.

That makes a lot of sense.I'd cut the heads off the bolts, take off the plate and likely you will find that with no pressure on the bolts they thread out easily, once you cut a new slot in the bolt and use enough lubricant to remove any corrosion.

Exactly. The left hand internal spiral bites into the nut or screw head and allows you to use a 3/8 ratchet for leverage. I have had quite a lot of success with them and there is no chance of them breaking off like the easy out ones. You do need a reasonable amount of screw head for it to grip.Interesting

Can you describe how the Irwin ‘Powergrip’ screw extractor work. Do they grip the outside of the screw head and allow the screw to turn anticlockwise

Exactly. The left hand internal spiral bites into the nut or screw head and allows you to use a 3/8 ratchet for leverage. I have had quite a lot of success with them and there is no chance of them breaking off like the easy out ones. You do need a reasonable amount of screw head for it to grip.

I first got onto them some years ago, when I needed to remove the badly damage anode holder on a Volvo 2003. It's nominally a 1/2" square, but had been badly rounded before I bought the boat. I'd tried several different methods - mole grips, filing flats for a spanner, tap spanner and others, but none worked as either there wasn't enough space to get a good grip or the metal was too soft (by the time I'd got decent flats there would have been little metal left!). The bolt-grips just worked, without fuss. In that case I lightly tapped the bolt grip onto the square and then used a ratchet driver; the anode holder unscrewed without any fuss.Exactly. The left hand internal spiral bites into the nut or screw head and allows you to use a 3/8 ratchet for leverage. I have had quite a lot of success with them and there is no chance of them breaking off like the easy out ones. You do need a reasonable amount of screw head for it to grip.

I don't know your engine type but if it does come to removing the whole pump there ia a useful tip for my Volvo 2020D.

It sounds drastic but is actually quite straightforward to put a wooden wedge under the engine and remove the engine mount that prevents access to the nuts on the back of the pump. From experience it is much less time consuming and frustrating than struggling with the awful access. I have a saildrive so there is no danger of upsetting the shaft alignment.

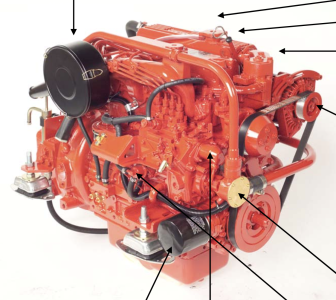

I hadn't realised that you had a Beta 2203, which is what I have also. But the access on mine is really easy, I can walk around the engine, especially the front where the pump is and remove the whole pump in 2 mins flat.

View attachment 186677

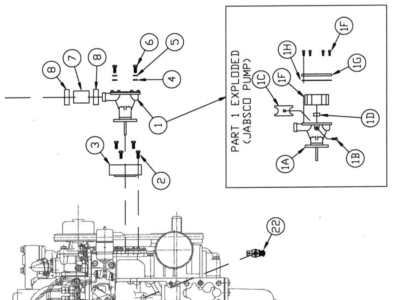

View attachment 186678

Items (2) are 6mm Allen head bolts, so should be easy enough to shift I'd have thought. What boat do you have? (mine's an R42, so a grey rather than red engine).