Refueler

Well-known member

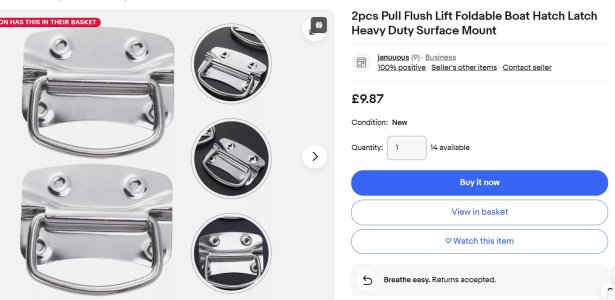

Bought a box of these :

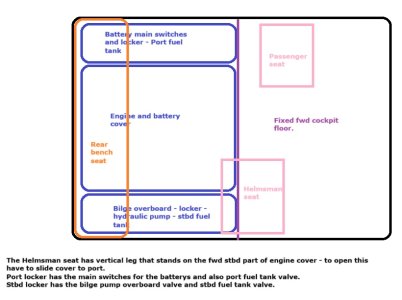

For fitting to my MoBo's cockpit floor sections ... at present I need a flat blade inserted in joint between them to lift ..

They are good ... stainless 316 etc. BUT why do so many items like this have the screws so close to the edge of cutout to fit ?? The hole to fix these into - not round but odd shape .... so extreme care needed to leave just that very narrow sliver for screw to go into !!

For fitting to my MoBo's cockpit floor sections ... at present I need a flat blade inserted in joint between them to lift ..

They are good ... stainless 316 etc. BUT why do so many items like this have the screws so close to the edge of cutout to fit ?? The hole to fix these into - not round but odd shape .... so extreme care needed to leave just that very narrow sliver for screw to go into !!