rib

Well-Known Member

Old deck lasted nearly 40 years no leaks

I only have a limited experience of teak decks as I had a cockpit seat area with teak decking on my moody, and the ply below rotted out. I replaced the whole thing reusing the old teak. It looked good but it was a hell of a job and it took the best part of the summer as I didn't realise the amount of work involved. Everything underneath needed replacing.Update:

The boat is now out of the water, rig out and undercover.

I got quote from Boatcraft, to replace the deck with a synthetic alternative. The quote includes stripping the old teak deck off and laying the new, but doesn't include any repairs that might be needed to the underlying deck.

The deck is effectively a side deck, about 350mm wide and 13.5m long, plus a small triangle of teak at the bow.

There are 3 filler caps on the port side, and 1 on the starboard side, both sides have a circulation plate for the inner shroud.

Triangular foredeck has an anchor locker hatch.

The quote is for £15,260 plus Vat.

This seem high to me, but I have no alternatives to compare it with.

Is anyone with real experience of replacing a teak deck willing to comment?

View attachment 165393

The best photo I could find just now, a narrow side deck.

Have you considered chiseling out and replacing the most outboard teak plank only?It's not the the condition of the teak deck, or the "pretend caulking" that's the problem, the teak deck is in relatively good condition, for it's age.

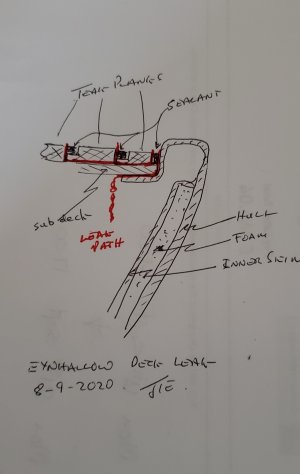

The problem is that the deck leaks, almost all the leaks come from the joint between the caulking and the bulwark.

perhaps this sketch will help.

Do you really think I could make a router work?Rout out the edge seam fill with flexible stuff…..maybe a pro can do the routing or set up a guide

Yes,just an idea ,from a distance it’s,just that an idea,but a router with a guide maybe away ,what about a guide fixed to the actual decking?Do you really think I could make a router work?

The inside edge of the bulwark could act as reference/guide with a block of wood the same height as the bulwark to keep the router level, but the distance from the top of the bulwark to the teak is at least 35mm plus 6mm or more for the teak. That's a long shank for a 1/4" router bit.

If that could be made to work it would be ideal, but as you can tell I'm sceptical.

Lateral thinking will save the day..You can't us a circular saw, the bulwark is curved. You finish up with a very big gap, and scared bulwark.

And

You can't get a router close enough at deck level. The base plate is too big, and one side would have to be curved.

I'm currently looking at a power chisel, something like a Arbortech Power Chisel and a 6mm flat blade, to carefully carve out the mastic. From the promotion video they look very controllable. Expensive for a one off job, but not compared to £20k bill.

You need a bigger router and there are long bearing guided router bits that would do the jobDo you really think I could make a router work?

The inside edge of the bulwark could act as reference/guide with a block of wood the same height as the bulwark to keep the router level, but the distance from the top of the bulwark to the teak is at least 35mm plus 6mm or more for the teak. That's a long shank for a 1/4" router bit.

If that could be made to work it would be ideal, but as you can tell I'm sceptical.

I think your chances of fixing that by routing out some caulk and re-caulking are the wrong side of zero.It's not the the condition of the teak deck, or the "pretend caulking" that's the problem, the teak deck is in relatively good condition, for it's age.

The problem is that the deck leaks, almost all the leaks come from the joint between the caulking and the bulwark.

perhaps this sketch will help.

View attachment 165941

The bond between the hull and deck has failed in several places.

..