IanCC

Active member

Hi,

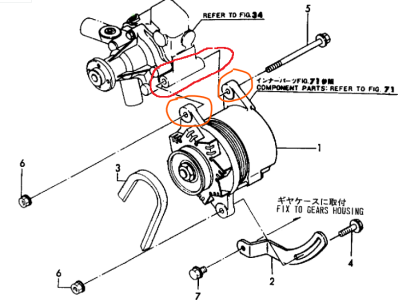

My stock hitachi alternator on my 3gm30f seems to be missing bushes. It's hole sizes are approx 9.5mm for m8 bolts. If someone could tell me how to fix this i would very much appreciate it.

Also the hole the bolt slides through, in the water pump(?), seems a bit sloppy so it's difficult to align pulleys radially. Is this normal? Or can i get it sleeved?

Thanks in advance for all and any input.

Ian

My stock hitachi alternator on my 3gm30f seems to be missing bushes. It's hole sizes are approx 9.5mm for m8 bolts. If someone could tell me how to fix this i would very much appreciate it.

Also the hole the bolt slides through, in the water pump(?), seems a bit sloppy so it's difficult to align pulleys radially. Is this normal? Or can i get it sleeved?

Thanks in advance for all and any input.

Ian