You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Whats a fair price for replacing the PSS shaft seal wear parts on my boat?

Hurricane

Well-Known Member

Actually, IIRC, testing the flow is in the Tides manual.i think through my own experiece its very important to check the water flow feed pipes ,if mine had been checked the second failure would have been avoided .

superchip

Well-Known Member

Actually, IIRC, testing the flow is in the Tides manual.

superchip

Well-Known Member

yes but unfortunately not in T C

Nito

Well-Known Member

Just looking at Nito's image back in #69 - just looks like the two mating faces are not sitting square, slightly skew, I am sure mine sat square....

Interesting report though, food for thought...

It’s interesting that you observed that also. Here is a better pic.

The concertinas at the top of the bellow are closer than those at the bottom.

I’ve been harbouring suspicions of engine alignment/adjustment on the engine mounts which perhaps are putting the shaft at an angle to the stern tube.

Interestingly, I went down there tonight to measure the bellows, they are actually at around 190mm vs 203-209mm that PSS suggest, so if anything they are a little too compressed which could possibly also be responsible for that one being a little askew?!

Nito

Well-Known Member

Also why is a jubilee clip attached to rotating shaft, is that normal, surely it would create an imbalance?

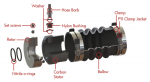

View attachment 116759

It’s belts and braces to prevent the rotor sliding back and letting the ocean in! PSS address this with their Pro kit by adding a locking collar to the shaft. They recommend on their website with the regular kit to add a jubilee clip.

Nito

Well-Known Member

you're joking, come and pull mine (45mm shafts) no fking way unless you do one finger pushups for fun (saw a scary clip on twitter last week I think)!

I'd hazzard a guess that ss rings and clips have slipped.

For good measure, I've marked with a permanent marker the point where the ring should be according to specs. Will be a good reference point down the line. If the blue line disappears, means the thing slipped.

Fnar

Good idea with marking them, I was going to do that but probably once I’ve replaced these. PSS recommend 6 years for the nitrile bellow and these must be coming up to that soon. Maybe they have lost some elasticity. I don’t think mine have loosened, measured this evening and if anything they are too compressed against PSS recommendations.

Cheers

Nito

MapisM

Well-Known Member

I don't think there's a "normal" setup, so only Sunseeker or someone familiar with your particular boat model can answer your question.Mine is a Sunseeker Portofino 400, I know there are cutlass bearings in the P brackets, but I don't know if there is any kind of seal/cutlass in the stern tube/shaft log, does anyone know if there normally would be?

FWIW, I'm aware of three possibilities:

- just ONE cutlass bearing on each shaft (on the P bracket, obviously);

- TWO of them, the second being somewhere along the thru-hull tube, on the external side of the seal;

- THREE of them, where there is a long(ish) thru-hull tube, with one at each end, both on the external side of the seal anyway.

Apropos, you said "any kind of seal/cutlass", but all the cutlass bearings that I came across (regardless of their number) are only meant to avoid shaft vibration and/or whiplash effect, but with no sealing function of any kind.

Not saying that there isn't some kind of cutlass bearing that also holds water pressure, but pretty sure I've never seen one - and neither heard of it.

Max Gland

Member

@Deleted User, if you don't sort this out it's going to be at the back of your mind, get it sorted and enjoy the limited season.

Nito

Well-Known Member

I don't think there's a "normal" setup, so only Sunseeker or someone familiar with your particular boat model can answer your question.

FWIW, I'm aware of three possibilities:

- just ONE cutlass bearing on each shaft (on the P bracket, obviously);

- TWO of them, the second being somewhere along the thru-hull tube, on the external side of the seal;

- THREE of them, where there is a long(ish) thru-hull tube, with one at each end, both on the external side of the seal anyway.

Apropos, you said "any kind of seal/cutlass", but all the cutlass bearings that I came across (regardless of their number) are only meant to avoid shaft vibration and/or whiplash effect, but with no sealing function of any kind.

Not saying that there isn't some kind of cutlass bearing that also holds water pressure, but pretty sure I've never seen one - and neither heard of it.

Thanks for the info Mapis, I’ll try and get some info from Sunseeker so I can be prepared for its next haul out. The shaft runs through a V drive with the coupling at the very front.

MapisM

Well-Known Member

FWIW, my boat also runs on V-drives, and it falls in the third category of my previous post (three cutlass bearings on each shaft).

But I don't think that depends on using V-drives or not, more likely a general boatbuilding design choice.

But I don't think that depends on using V-drives or not, more likely a general boatbuilding design choice.

Nito

Well-Known Member

That is indeed VERY scary.

I'm sure others on here will disagree with me but now that you have said that, if I were you, I would change them for Tides seals.

You would have an issue though - there isn't much space to get any seal in there.

Especially if you wanted a spare Tides style replacement seal on the shaft.

I think I would explore the option though.

Just the thought of getting on board one day, starting up and shredding the bellows, scares the living daylights out of me.

Who checks their glands after starting and moving off!!

I think the chances of this happening are very unlikely. However, it is something to be aware of, especially for those who have their boats in the med and the like and aren’t regularly on their boats. With Covid lots of boats have been dormant and it would be worth those with PSS seals ‘burping’ them momentarily just to be sure that this can’t happen. I would think it would take a long lay up for this to occur in reality. Ironically I believe this boat was on Tides seals originally fitted by the second to last owner.

I’m happy with the PSS concept, more so now that I have watched all the videos and gained a better understanding of how they work and what their limitations etc are. A shredded bellow would be a disaster, but they are very solid and better protected from barnacles and the like than an outdrive bellow! There are many out there performing perfectly so as long as installed correctly, they should work fine! (Famous last words!)

Last edited:

Nito

Well-Known Member

when i arrived in Opesa from Majorca as soon as we come off the plane after a very short time the bilge pumps started working so as soon as i was tied up i went in the engine rom and you could hear gallons of water entering the boat.

the shaft seal was completely destroyed and the feed pipes both ripped off,

i undone the clips on the bellows ,slid it up the shaft and forced rags in-between the shaft and stern tube which eventually stopped the flow.

the whole seal,housing bellows and clips lasted about eight hours before completely melting though lack of coolant water.

the feed pipe from the engine was partially blocked causing this to happen again so although t.c did the repair what they didn't do was find out why it failed . i contacted tidal seals and thats who told me it needed eleven litres a minute to keep it cool.

i passed this information on to TC they then checked it and replaced the restricted feed pipe

Quick thinking by removing the jubilees and stuffing the stern tube. I had been wondering what I would do in such a situation, this seems a good solution to stem that flow!! Hopefully I’ll never need to.

MapisM

Well-Known Member

Nito, your bellow does look too compressed just by the look of it.

And even if I'm just going by common sense, and I have no idea if it's mentioned in some of their manuals, I suspect that any compression higher than what is sufficient to grant a good seal should be avoided.

In fact, on one hand it's bound to wear out the contact sealing area faster, and OTOH it might also increase (Heaven forbid!) the bonding risk after long periods of no usage that you mentioned.

And even if I'm just going by common sense, and I have no idea if it's mentioned in some of their manuals, I suspect that any compression higher than what is sufficient to grant a good seal should be avoided.

In fact, on one hand it's bound to wear out the contact sealing area faster, and OTOH it might also increase (Heaven forbid!) the bonding risk after long periods of no usage that you mentioned.

Nito

Well-Known Member

Hi Mapis,

I would agree with that. According to the PSS literature it should be nearly 20mm slacker. Of course that means that the rubber seals in the rotor will likely need to be sitting just where the jubilee is, and typically, what are the chances that the jubilee has scored the shaft!! The PSS pro kit has a much neater solution with its locking collar.

I would agree with that. According to the PSS literature it should be nearly 20mm slacker. Of course that means that the rubber seals in the rotor will likely need to be sitting just where the jubilee is, and typically, what are the chances that the jubilee has scored the shaft!! The PSS pro kit has a much neater solution with its locking collar.

John100156

Well-Known Member

It sounds like you know what you're going to do, if I were you, I would bite the bullet remove the old PSS clean everything up, fit new PSS, check flow rates and play in cutlass bearing and replace only if necessary, load up the beer fridge and enjoy the rest of the season there will be more problems to resolve shortly, there always is...!

Best of luck sorting this out....

Best of luck sorting this out....

Max Gland

Member

It sounds like you know what you're going to do, if I were you, I would bite the bullet remove the old PSS clean everything up, fit new PSS, check flow rates and play in cutlass bearing and replace only if necessary, load up the beer fridge and enjoy the rest of the season there will be more problems to resolve shortly, there always is...!

Best of luck sorting this out....

Couldn't agree more, it will be on the back of your mind for the session.

petem

Well-Known Member

You know what you guys need....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

D

Deleted User YDKXO

Guest

It sounds like you know what you're going to do, if I were you, I would bite the bullet remove the old PSS clean everything up, fit new PSS, check flow rates and play in cutlass bearing and replace only if necessary, load up the beer fridge and enjoy the rest of the season there will be more problems to resolve shortly, there always is...!

Best of luck sorting this out....

That is certainly my thinking. I dont want to be ripped off but at the same time, given the very limited time I spend on my boat in a normal year let alone this year, I dont want the hassle of worrying about the seals. I have learnt this morning that my PSS seals have been inspected in situ by 3 separate people with technical knowledge and all are of the opinion that the seal rings have to be replaced as well as the bellows so I guess I will have to follow their advice

As Mapism of this parish often says, BOAT = Bring on another thousand

D

Deleted User YDKXO

Guest

Nito, your bellow does look too compressed just by the look of it.

Yes that was my first thought when I saw the pic. The bellow looks like its been compressed almost as far as it can possibly go