wiggy

Well-known member

Why does my belt need constant adjusting?

I do get lots of black dust.Hmmm, thinking alignment? any black dust?

I ran a 2020 for 11 years and never needed to adjust the belt tension.

Subsequently have a Yanmar 4J4E and it needs adjusting 4 times a year and distributes black particles everywhere eating a belt every year.

I am advised by a Yanmar agent 'normal for that engine'???!!!!

I do get lots of black dust.

Running an alternator bigger than 90A @12v on a single Vee belt is always going to over stress the belt even if it is cogged and on clean pulleys. The slightest misalignment in any plane of even one pulley will make it much worse.

I find the modern single swivel bolt mounted alternators are often out of line when under load even if tight. I have had multiple bolt fractures with these flexing under load.

Gates belts seem better than most. The old Fenner belts were good but seem to be unavailable now.

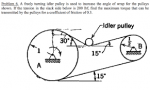

Is it possible to add an idler pulley to get more wrap?Last year was my first season on the new boat with a Yanmar 4J3E engine. Lots of black dust and belt adjustment required. Alignment is good, pulley condition good and alternator mounts aren’t slackening off. It has a Balmer alternator. If memory serves it is 80A, only 10A more than standard but with a smart controller that allows it to charge the batteries quicker. Next season I’m going to try a cogged belt, and if that doesn’t help I’ll convert all the pulleys and fit a multi-v belt.

I had a similar issue with a 2030. I swopped it for a Gates "toothed" belt and it solved the problem.Why does my belt need constant adjusting?

Is it possible to add an idler pulley to get more wrap?

Another option is double vee belts, although this is dependent on there being room for the longer pulleys; it does have the advantage of using vee belts which are generally easier to obtain if you are somewhere less well connected.Last year was my first season on the new boat with a Yanmar 4J3E engine. Lots of black dust and belt adjustment required. Alignment is good, pulley condition good and alternator mounts aren’t slackening off. It has a Balmer alternator. If memory serves it is 80A, only 10A more than standard but with a smart controller that allows it to charge the batteries quicker. Next season I’m going to try a cogged belt, and if that doesn’t help I’ll convert all the pulleys and fit a multi-v belt.

All things are possible if you have the engineering expertise and tooling. I don’t have much of the former and very little of the latter. Worth considering though.