philwebb

Member

Hi Folks,

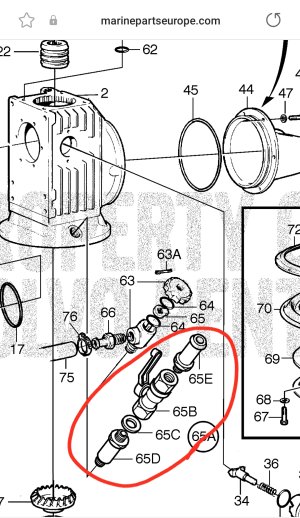

I‘ve got a S120 sail drive and the seacock has more or less had it. I went from the original plastic head to a modified plumbing valve head, but now I need a spanner to turn it. What have other people done about this? I’m thinking that a suitable (bronze?) plumbing valve might do the job if the thread is compatible.

I‘ve got a S120 sail drive and the seacock has more or less had it. I went from the original plastic head to a modified plumbing valve head, but now I need a spanner to turn it. What have other people done about this? I’m thinking that a suitable (bronze?) plumbing valve might do the job if the thread is compatible.