GooseGas

Member

Hi all,

We’ve had a shocking 6 months with our D3s. Would love some thoughts.

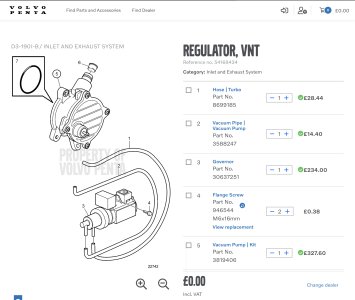

Both engines wouldn’t make it up to plane. Perform fine up to 2000rpm and 50-60 boost pressure. Both engines ‘let go’ and fault with turbo actuator or VNT valve faults. We could move the vanes by hand. Everything moving and free.

Replaced both VNT valves. No change. Decided to give it a birthday.

Pulled out both engines:

- new turbos

- new harnesses both sides

- new couplings

- intercoolers cleaned out

- fuel filters changed

- fuel lines checked

- full servicing

- both legs serviced

$40k plus bill.

Sea trial today. Same result. F&%#*k.

Both engines into limp mode, run up fine to 2000-2100rpm then just won’t build pressure past 50/60. Won’t plane. Both throw up turbo actuator faults at the same time.

Any thoughts would be appreciated. Feeling pretty gutted after spending a lot, for no result.

We’ve had a shocking 6 months with our D3s. Would love some thoughts.

Both engines wouldn’t make it up to plane. Perform fine up to 2000rpm and 50-60 boost pressure. Both engines ‘let go’ and fault with turbo actuator or VNT valve faults. We could move the vanes by hand. Everything moving and free.

Replaced both VNT valves. No change. Decided to give it a birthday.

Pulled out both engines:

- new turbos

- new harnesses both sides

- new couplings

- intercoolers cleaned out

- fuel filters changed

- fuel lines checked

- full servicing

- both legs serviced

$40k plus bill.

Sea trial today. Same result. F&%#*k.

Both engines into limp mode, run up fine to 2000-2100rpm then just won’t build pressure past 50/60. Won’t plane. Both throw up turbo actuator faults at the same time.

Any thoughts would be appreciated. Feeling pretty gutted after spending a lot, for no result.