Captaincape

New member

Just picked up a bit more engine than I need but I'm going to try and shoe horn it in. Price seemed good and it's in good shape.

The water lines were disconnected for shipping and I'm not sure the map to reconnect.

I'm going to bench test the engine before attempting install.

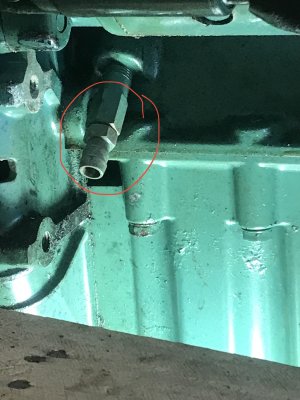

It's the 2003t and I think I see most of the connections but unsure about the u shaped piping which appears to have a vent. It appears to connect to where the two cut lines are.the itAnd the three fittings one from fresh water pump and one on side of block below starter and one in block slightly above and behind fresh water pump.

The water lines were disconnected for shipping and I'm not sure the map to reconnect.

I'm going to bench test the engine before attempting install.

It's the 2003t and I think I see most of the connections but unsure about the u shaped piping which appears to have a vent. It appears to connect to where the two cut lines are.the itAnd the three fittings one from fresh water pump and one on side of block below starter and one in block slightly above and behind fresh water pump.