You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nut on folding prop.

- Thread starter Sneaky Pete

- Start date

PabloPicasso

Well-Known Member

On my previous boat the volvo 2 bladed folding prop undid in the usual lefty loosey manner. There was a small central bolt and larger bronze nut held together securely by a tab washer.

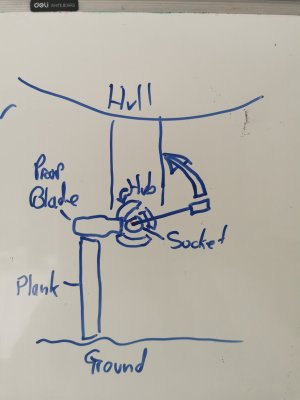

To undo that nut I'd put a socket on, then insert a prop blade as far into its castlated gap as it'd go, rotate blade/hub into a horizontal postion, support the blade edge beneath on a stout plank wedged against the ground to stop the whole thing rotating when I put in the extension bar and socket driver to undo.

But you knew all that.

From your photo it looks like you've already removed the tab washer and central bolt.

To undo that nut I'd put a socket on, then insert a prop blade as far into its castlated gap as it'd go, rotate blade/hub into a horizontal postion, support the blade edge beneath on a stout plank wedged against the ground to stop the whole thing rotating when I put in the extension bar and socket driver to undo.

But you knew all that.

From your photo it looks like you've already removed the tab washer and central bolt.

Last edited:

Neeves

Well-Known Member

Our props were 3 bladed Volvos.

You need a very large socket to remove the large nut. The large socket was bigger than the one in my socket kits (I have normal sockets and long sockets) and I had to source a new socket - and sourcing single big sockets is not easy. I don't recall how big - but I could check. The tab washer is one use only, the tabs work harden and break off quite easily. If you are lucky, as there are lots of tabs, you might use one tab for one installation and still have an unused tab for the next installation. Tab washers are cheap - I would not try to save money

I don't trust the tabs - and use blue Loctite as well.

I don't recall that you need to torque up the inner bolt nor the big nut. Its the tab washer holding it secure, and the fact the threads on the little bolt and big nut are 'different', hence my use of blue Loctite.

You obviously need the engine in gear - ideally held stationary in addition to being in gear.

If its fouled its easier to clean the prop on the shaft, I used a steel brush on an angle grinder - which keyed the prop for painting. Once you have cleaned the prop handle it with gloves, grease from you hands will reduce the effectiveness of the key.

Jonathan

You need a very large socket to remove the large nut. The large socket was bigger than the one in my socket kits (I have normal sockets and long sockets) and I had to source a new socket - and sourcing single big sockets is not easy. I don't recall how big - but I could check. The tab washer is one use only, the tabs work harden and break off quite easily. If you are lucky, as there are lots of tabs, you might use one tab for one installation and still have an unused tab for the next installation. Tab washers are cheap - I would not try to save money

I don't trust the tabs - and use blue Loctite as well.

I don't recall that you need to torque up the inner bolt nor the big nut. Its the tab washer holding it secure, and the fact the threads on the little bolt and big nut are 'different', hence my use of blue Loctite.

You obviously need the engine in gear - ideally held stationary in addition to being in gear.

If its fouled its easier to clean the prop on the shaft, I used a steel brush on an angle grinder - which keyed the prop for painting. Once you have cleaned the prop handle it with gloves, grease from you hands will reduce the effectiveness of the key.

Jonathan

Neeves

Well-Known Member

You might want to check this but the big nut 'inside' the hub might accept a 30mm socket. I'm doing this from memory

The large nut, and even the small nut, will surely vary dependent on the size of the hub and/or props? Our props, 3 blades, must have been 'about' 200mm diameter

The large nut, and even the small nut, will surely vary dependent on the size of the hub and/or props? Our props, 3 blades, must have been 'about' 200mm diameter

Halo

Well-Known Member

You need to flatten the tab washer (looks like it’s still there) which is folded up alongside one of the hex flats. Do this with a big screwdriver and gentle hammer tapping. Then find a quality socket set that fits.

I found difficulty in stopping the hub rotating. To solve this problem I got a length of good quality wood and shaped one end to fit very snugly into the jaws where the blades fitted and long enough to jam against the bottom of the boat to stop rotation. This bit of wood has worked for years and allows me to get some torque on.

Only re tighten to the recommended torque setting and don’t use any locking gue on the big bolt only the little one that is in the centre of the bigger bolt. If you do you will struggle to get it off in future

I found difficulty in stopping the hub rotating. To solve this problem I got a length of good quality wood and shaped one end to fit very snugly into the jaws where the blades fitted and long enough to jam against the bottom of the boat to stop rotation. This bit of wood has worked for years and allows me to get some torque on.

Only re tighten to the recommended torque setting and don’t use any locking gue on the big bolt only the little one that is in the centre of the bigger bolt. If you do you will struggle to get it off in future

PabloPicasso

Well-Known Member

Why have the engine in gear? I'd be worried loading the gearbox up in a way its not designed for might cause expensive damage.You obviously need the engine in gear - ideally held stationary in addition to being in gear.

If its fouled its easier to clean the prop on the shaft, I used a steel brush on an angle grinder - which keyed the prop for painting. Once you have cleaned the prop handle it with gloves, grease from you hands will reduce the effectiveness of the key.

Jonathan

Not necessary. Stop the prop hub rotating as I described above in post #2

Last edited:

PabloPicasso

Well-Known Member

The central bolt and tab washer have been removed already.You need to flatten the tab washer (looks like it’s still there) which is folded up alongside one of the hex flats. Do this with a big screwdriver and gentle hammer tapping. Then find a quality socket set that fits.

I found difficulty in stopping the hub rotating. To solve this problem I got a length of good quality wood and shaped one end to fit very snugly into the jaws where the blades fitted and long enough to jam against the bottom of the boat to stop rotation. This bit of wood has worked for years and allows me to get some torque on.

Only re tighten to the recommended torque setting and don’t use any locking gue on the big bolt only the little one that is in the centre of the bigger bolt. If you do you will struggle to get

Attachments

PabloPicasso

Well-Known Member

Sneaky Pete

Well-Known Member

Thanks I'm using a M24 socket I'm hoping that it's right hand, but it feels like it is seized I know it's not it just tight.You might want to check this but the big nut 'inside' the hub might accept a 30mm socket. I'm doing this from memory

The large nut, and even the small nut, will surely vary dependent on the size of the hub and/or props? Our props, 3 blades, must have been 'about' 200mm diameter

Sneaky Pete

Well-Known Member

Yes both are now off, I'll try your method of rotation prevention. M24 socket on nut very tight. Thanks.On my previous boat the volvo 2 bladed folding prop undid in the usual lefty loosey manner. There was a small central bolt and larger bronze nut held together securely by a tab washer.

To undo that nut I'd put a socket on, then insert a prop blade as far into its castlated gap as it'd go, rotate blade/hub into a horizontal postion, support the blade edge beneath on a stout plank wedged against the ground to stop the whole thing rotating when I put in the extension bar and socket driver to undo.

But you knew all that.

From your photo it looks like you've already removed the tab washer and central bolt.

fredrussell

Well-Known Member

If all else fails a bit of heat on the nut may help. Someone may have put loctite on it.

Neeves

Well-Known Member

I'm assuming you have released the tabs on the tab washer....?

J

J

Neeves

Well-Known Member

I was a bit, very, twitchy on using heat. I understood the prop was constructed with a polymer sleeve (which may be totally incorrect) and applying heat to the nut might damage the sleeve (if it exists). Penetrating oil would be my first port of call or WD 40. If the shaft is immobilised you should be able to apply plenty of grunt.

Jonathan

Jonathan

Neeves

Well-Known Member

I'm not sure if it makes any difference but my socket took a 1/2" drive.

PabloPicasso

Well-Known Member

Try lots and lits of boiling water as a release agent too.

Many many kettles full

Many many kettles full

stuartwineberg

Well-Known Member

The torque setting for the nut is 70Nm according to the Volvo manual for folding prop on saildrive

PabloPicasso

Well-Known Member

Yes, give it a go. Stopping the whole thing turning is likely the issue.Yes both are now off, I'll try your method of rotation prevention. M24 socket on nut very tight. Thanks.

If that doesn't work, and you're stuck, see if you can borrow a dewalt (or similar) battery powered impact driver, but make sure you use the special sockets designed for use with them.

Ask around the yacht club/boat yard etc. Someone is likely to have one!!

If you're really stuck hire, or even buy one

PabloPicasso

Well-Known Member

Well, any joy?

Other threads that may be of interest

- Replies

- 2

- Views

- 177

- Replies

- 3

- Views

- 140

- Replies

- 0

- Views

- 72