geem

Well-Known Member

This week, I have been sorting out problems on professionally installed lithium battery system on a friends boat here in Antigua. The system is 7 years old. It was very nicely installed and would have been considered state of the art at the time.

It reminded me why complex is not the same as reliable.

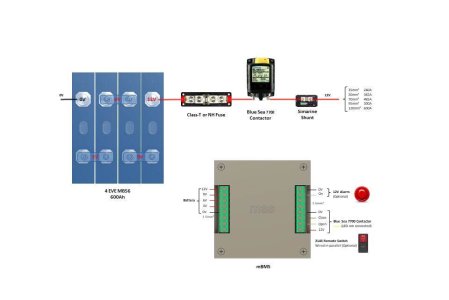

Its a 12v system using 16 Winston cells of 200Ah each. Its built as a single battery with 4 cells connected in parallel, then series wired such that you get an effective 800Ah cell x 4.

The BMS is a contactor type by REC with a charge bus and a seperate discharge bus.

The REC selling point is that is can communicate with the Victron MPPT, GX display and the Quattro inverter via canbus. It also has its own REC mini display.

Engine alternators charge the lithium directly using their own inbuilt temperature sensing. They have no external regulator.

The downside of this system is you have numerous single points of failure. One battery and all the ancillaries that go with that mean that when it goes wrong, you go dark ship.

Things we found.

The bms uses RS485 and canbus to communicate. In a marine environment these multi-pin connectors need to be waterproof. We had voltage drops and canbus failure due to numerous bad connections.

The huge 800Ah cells can't easily be balanced by the REC 2A active balancer.

When canbus goes wrong due to poor connections all across the system ( mppt canbus connection, GX connection, REC bms connections were all faulty) numerous faults and miss information occur. (Note that the boat is dry and free from obvious moisture. Everything looks pristine).

The mppt wasn't getting the correct voltage from the BMS via canbus. It thought the batteries were at 14.5V when they were actually at 13.7V so it stopped charging early. It doesn't seem to have done any meaningful cell balancing for a long time.

Cell 3 was hitting a 250mV difference and the BMS tripped in the middle of the night, causing an audible alarm to go off on the Victron GX display that wasn't possible to mute without pulling the wires out of the back of the GX.

My pal had to sleep with a torch by his bed and get up to remove the wires before going back to bed.

We are currently using a benchtop power supply to raise cell 3 voltage. It been installed since yesterday morning and is still going at 4A, 3.6v. The cell voltage has gone up so we didnt get the 0.25v cell differential alarm going off over night.

We have a WiFi module on route from the USA so we can interrogate all the settings in the BMS and determine what we need to change. When the battery was built and the REC BMS was installed, it was considered that the owner wouldn't want access to the BMS settings.

If it was my own boat, I would disassemble the cells to make 4 seperate 200A batteries at 200Ah each at 12v. I would use a JK BMS on each cell and wire the batteries with an isolator each and a class T fuses each.

I would install a Victron Dc/Dc chargers for each engine and do away with the canbus communication.

We currently have the Victron MPPT using a newly installed Victron smart shunt independently of the RECs own shunt. This bit works well.

Canbus has added nothing to the reliability of this system. In fact, we found that if we unplug the GX display the REC BMS will not boot up. An add on to the system should not stop the REC BMS from functioning.

Multiple batteries with their own bms would provide resilience that this current system does not have.

Letting the MPPT control their own charge provides and independent method of charging that doesn't rely on canbus.

Ditto DC/DC chargers on each engine.

In my opinion, the BMS should only look after the safety of the battery. Asking it to do other tasks put all your eggs in one basket.

REC are based in Slovenia with an agent in the USA. When you are in Antigua, excellent service back-up or redundancy are your only two options. For this location, redundancy is the better option

It reminded me why complex is not the same as reliable.

Its a 12v system using 16 Winston cells of 200Ah each. Its built as a single battery with 4 cells connected in parallel, then series wired such that you get an effective 800Ah cell x 4.

The BMS is a contactor type by REC with a charge bus and a seperate discharge bus.

The REC selling point is that is can communicate with the Victron MPPT, GX display and the Quattro inverter via canbus. It also has its own REC mini display.

Engine alternators charge the lithium directly using their own inbuilt temperature sensing. They have no external regulator.

The downside of this system is you have numerous single points of failure. One battery and all the ancillaries that go with that mean that when it goes wrong, you go dark ship.

Things we found.

The bms uses RS485 and canbus to communicate. In a marine environment these multi-pin connectors need to be waterproof. We had voltage drops and canbus failure due to numerous bad connections.

The huge 800Ah cells can't easily be balanced by the REC 2A active balancer.

When canbus goes wrong due to poor connections all across the system ( mppt canbus connection, GX connection, REC bms connections were all faulty) numerous faults and miss information occur. (Note that the boat is dry and free from obvious moisture. Everything looks pristine).

The mppt wasn't getting the correct voltage from the BMS via canbus. It thought the batteries were at 14.5V when they were actually at 13.7V so it stopped charging early. It doesn't seem to have done any meaningful cell balancing for a long time.

Cell 3 was hitting a 250mV difference and the BMS tripped in the middle of the night, causing an audible alarm to go off on the Victron GX display that wasn't possible to mute without pulling the wires out of the back of the GX.

My pal had to sleep with a torch by his bed and get up to remove the wires before going back to bed.

We are currently using a benchtop power supply to raise cell 3 voltage. It been installed since yesterday morning and is still going at 4A, 3.6v. The cell voltage has gone up so we didnt get the 0.25v cell differential alarm going off over night.

We have a WiFi module on route from the USA so we can interrogate all the settings in the BMS and determine what we need to change. When the battery was built and the REC BMS was installed, it was considered that the owner wouldn't want access to the BMS settings.

If it was my own boat, I would disassemble the cells to make 4 seperate 200A batteries at 200Ah each at 12v. I would use a JK BMS on each cell and wire the batteries with an isolator each and a class T fuses each.

I would install a Victron Dc/Dc chargers for each engine and do away with the canbus communication.

We currently have the Victron MPPT using a newly installed Victron smart shunt independently of the RECs own shunt. This bit works well.

Canbus has added nothing to the reliability of this system. In fact, we found that if we unplug the GX display the REC BMS will not boot up. An add on to the system should not stop the REC BMS from functioning.

Multiple batteries with their own bms would provide resilience that this current system does not have.

Letting the MPPT control their own charge provides and independent method of charging that doesn't rely on canbus.

Ditto DC/DC chargers on each engine.

In my opinion, the BMS should only look after the safety of the battery. Asking it to do other tasks put all your eggs in one basket.

REC are based in Slovenia with an agent in the USA. When you are in Antigua, excellent service back-up or redundancy are your only two options. For this location, redundancy is the better option