eddystone

Well-Known Member

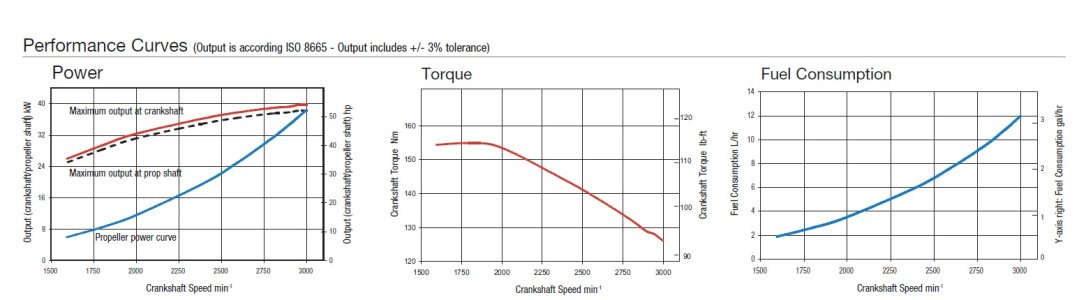

I found a fuel consumption curve for Volvo MD22L but there are two curves, one for full load and one for calculated propeller load at an assumed gearbox reduction ratio (in this case 2.5:1)

Which is best indicator of real world consumption?

Which is best indicator of real world consumption?