Graham376

Well-Known Member

This will not work. The motor will spin, but the starter will no engage.

Yes it does, I've done it several times in the past. In the OP's case, it wouldn't of course due to the negative fault later found.

This will not work. The motor will spin, but the starter will no engage.

With what engine ?Yes it does, I've done it several times in the past. In the OP's case, it wouldn't of course due to the negative fault later found.

Disagree all you want and feel free to waste your time in your garage with your antique 2GM starter. The OP has a modern, pre-engaged starter and it categorically WILL NOT start by shorting the two M8 terminals on the starter solenoid.Having succesfully started my old 2GM (oft discussed problem activating solenoid) with an 8mm allen key across the solenoid M8 studs, I disagree. As to the circuit which causes the solenoid to activate during this I neither know or particularly care. If I can be bothered I may investigate with the redundant (2GM long gone) spare in the garage.

With what engine ?

The solenoid may pull in if the battery is well charged by just shorting the solenoid contacts because the solenoid has 2 windings, the pull in which the has spade connector, and the hold in which is connected to the starter motor connection on the solenoid. If you are lucky and the battery is really good the hold in winding may be strong enough alone to pull in the pinion and hence the solenoid contacts too.Several, I served apprenticeship in motor trade. My old Capri had a sticking starter and if hammer tap didn't free it, short across the terminals did.

I have also started several old engines, fitted with inertia starters, but the OP has a pre-engaged starter, shorting the battery and motor terminals on the solenoid only spins the motor, it is physically impossible to start the engine this way.Several, I served apprenticeship in motor trade. My old Capri had a sticking starter and if hammer tap didn't free it, short across the terminals did.

I had exactly tha same happen to me a few years ago and now keep a hefty pair of jump leads on the boat to be used for fault finding. The fault turned out to be with the cable that ran from the starter battery to the engine block. The fault in the bad cable was not visible to the naked eye.We left Lerwick this afternoon to begin the journey home with a wee trip to Mousa to visit the famous broch.

We had a lovely sail down under genoa. Abeam Mousa I doused the genoa and turned the ignition key prior to having a look round the scanty anchorage. Nothing, not even a click.

More in hope than anger I ruffled the wires behind the panel randomly, and to my relief the Beta surged into life when I turned the key.

No way we were going to anchor off Mousa with a potential engine issue, so we repaired to Sandwick, where we are now safely anchored and protected from all wind directions except South, should be good for the next three days. The engine will not start, and rummelling the wires again made no difference.

I have time to sort this, I am just lacking the knowledge.

Here is what I do know/have checked;

a) there are no obvious loose wires on the ignition switch

b) the engine block earth, or what I think is the engine block earth, looks/feels OK

c) there is no click when attempting to start, no ignition light and no voltage drop

d) I have unplugged and reconnected the main engine multiplug, to no effect

This is out of the blue, engine has started instantly on every attempt on this trip

I have a multimeter and can follow basic instructions, but otherwise am an electrical numpty. If people could talk me through some basic fault finding I would be very grateful, otherwise it is an upwind sail back to Lerwick to find an engineer.

- W

Disagree all you want and feel free to waste your time in your garage with your antique 2GM starter. The OP has a modern, pre-engaged starter and it categorically WILL NOT start by shorting the two M8 terminals on the starter solenoid.

The solenoid may pull in if the battery is well charged by just shorting the solenoid contacts because the solenoid has 2 windings, the pull in which the has spade connector, and the hold in which is connected to the starter motor connection on the solenoid. If you are lucky and the battery is really good the hold in winding may be strong enough alone to pull in the pinion and hence the solenoid contacts too.

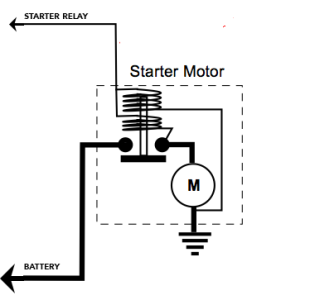

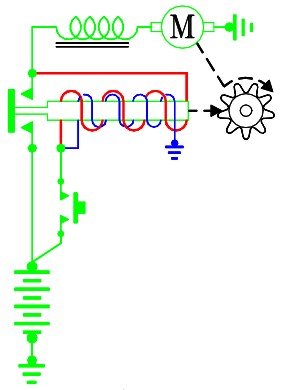

A couple of diagrams ( choose the monochrome one or the pretty coloured one according to your personal preference) which will explain how shorting the two main terminals might just engage the starter.I have also started several old engines, fitted with inertia starters, but the OP has a pre-engaged starter, shorting the battery and motor terminals on the solenoid only spins the motor, it is physically impossible to start the engine this way.

Happy days with pre-solenoid starters. They either didn't work because of no lubricant or too much, usually grease. A tap usually did it, especially if unlubricated. Sometimes you'd get an electrical fault (brushes, connection, etc.) and a tap would still get it to work.Several, I served apprenticeship in motor trade. My old Capri had a sticking starter and if hammer tap didn't free it, short across the terminals did.

P.S. Just remembered, did it on our last boat engine Thornycroft T80 (Mitsubishi K4D).

This ^^^^^^A couple of diagrams ( choose the monochrome one or the pretty coloured one according to your personal preference) which will explain how shorting the two main terminals might just engage the starter.

I am surprised in does though.

View attachment 197909View attachment 197910

May I suggest you actually try doing it, but do try and avoid welding the shorting devive to the studs - it makes undoing the nuts more difficult. And despite your implication, my 2GM had a pre-engaged starter, that's probably why it had a solenoid attached with terminals to short.Disagree all you want and feel free to waste your time in your garage with your antique 2GM starter. The OP has a modern, pre-engaged starter and it categorically WILL NOT start by shorting the two M8 terminals on the starter solenoid.

Stay out of this, Webby, your starting problem is sorted! A statement has been made, and doubled down on, that generations of Yanmar owners know from personal experience is erroneous.And of course if the issue is a poor earth then shorting across the solenoid will do nothing . . .

I'd also be surprised if it does work, but it seems it sometimes does, at least with a 2GM starter.A couple of diagrams ( choose the monochrome one or the pretty coloured one according to your personal preference) which will explain how shorting the two main terminals might just engage the starter.

I am surprised in does though.

View attachment 197909View attachment 197910

Shorting the M8 terminals (if it works) will result in the "dog" trying to align with the ring gear at high speed which could cause damage such as a broken tooth or excessive wear, the pre engage is an early mechanical make and a late electrical make (as you know anyways) causing least mechanical wear.I'd also be surprised if it does work, but it seems it sometimes does, at least with a 2GM starter.

That said, given the option of shorting the spade to the battery cable, which is sure to work (if anything will), or shorting the M8 terminals, which might occasionally work, i'm not sure why anyone would do the latter.

I think it can...arcing can damage the thread, high speed engagement of the pinion and ring gear can damage both or either, can cause excessive stress on bearings and casting, and risk of bending the shaft.And does shorting the studs cause any damage?

There is no mechanism to 'ram a pinion into the ring gear'. The pinion is firmly attached to the motor rotor. The whole rotor needs to move, energised by the solenoid, before engagement can occur. Totally different from a Bendix gear, which was used successfully for almost 50 yearsI think it can...arcing can damage the thread, high speed engagement of the pinion and ring gear can damage both or either, can cause excessive stress on bearings and casting, and risk of bending the shaft.

The pre engage puts the pinion (dog) teeth into the ring gear teath before the starter motor rotates or has any energy.

The inertia type throws the pinion (dog) into the ring gear prior the the starter motor being under full.load...

Shorting the terminals on a pre engage type puts the starter motor in full speed with a lot of energy at the same time trying to ram a pinion into the ring gear...

Yes it works but it's not designed and built fot that abuse, even less so with today's plastic gear box in some starter motors.