Ian_Edwards

Well-known member

Hi,

I've revamped the electrical system on my Southerly 46RS this winter.

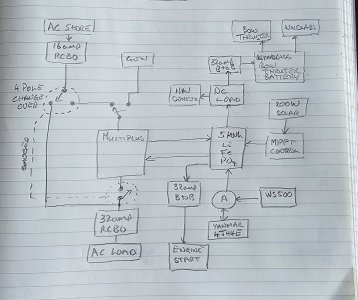

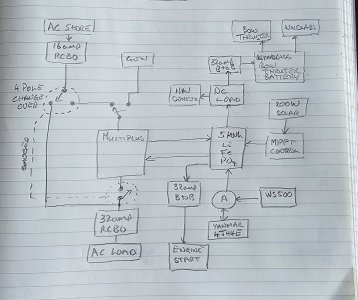

This is a schematic of the layout. I haven’t included DC fuses. It's just the general layout.

There's has been quite a lot of input from the forum over the winter, so thanks for that.

The AC side start with a 16amp RCBO, I haven’t included a galvanic isolator. The boat spends very little time in a marina, just few days ayear. This is followed by a switch which bypasses the Muliplus. This switch is only used in winter when the boat is out of the water and want to use the AC without charging the battery. It's a 4 pole switch, the 4th pole being used to disconnect the output from the Multiplus, so that it is completely isolated from the AC supply. I did this because I wasn't sure how the Multiplus would react to having AC on the output, but no AC on the input.

The next switch selects between shore power and Generator. The output from the Multiplus goes through a 32amp RCBO to the boats AC supply. I used 32amps because the Multiplus can reinforce the AC output if the AC load exceeds the 16amp input limit.

The Multiplus is connected to 5kWh of LiFePO4 domestic battery. Which in turn is connected to the engine alternator. I connected the alternator to the LiFePO4 because it will take all the energy the alternator will produce, unlike a lead acid, where the charging efficency drop as the SOC increases. The alternator is controlled by a WS500, which limits the output of the120amp alternator to 80amps, to protect it from overheating. Although I may increase that a little after I see how well the alternator copes.

The LiFePO4 batteries charges lead acid batteries for engine start and the bow thruster and windlass batteries through 32amp BtoBs. That ensures that these batteries are always fully charged. I also have switch to directly connect the domestic and starter batteries.

The LiFePO4 batteries are charged by 200W of solar through a MPPT charge controller.

Observations and comments?

I've revamped the electrical system on my Southerly 46RS this winter.

This is a schematic of the layout. I haven’t included DC fuses. It's just the general layout.

There's has been quite a lot of input from the forum over the winter, so thanks for that.

The AC side start with a 16amp RCBO, I haven’t included a galvanic isolator. The boat spends very little time in a marina, just few days ayear. This is followed by a switch which bypasses the Muliplus. This switch is only used in winter when the boat is out of the water and want to use the AC without charging the battery. It's a 4 pole switch, the 4th pole being used to disconnect the output from the Multiplus, so that it is completely isolated from the AC supply. I did this because I wasn't sure how the Multiplus would react to having AC on the output, but no AC on the input.

The next switch selects between shore power and Generator. The output from the Multiplus goes through a 32amp RCBO to the boats AC supply. I used 32amps because the Multiplus can reinforce the AC output if the AC load exceeds the 16amp input limit.

The Multiplus is connected to 5kWh of LiFePO4 domestic battery. Which in turn is connected to the engine alternator. I connected the alternator to the LiFePO4 because it will take all the energy the alternator will produce, unlike a lead acid, where the charging efficency drop as the SOC increases. The alternator is controlled by a WS500, which limits the output of the120amp alternator to 80amps, to protect it from overheating. Although I may increase that a little after I see how well the alternator copes.

The LiFePO4 batteries charges lead acid batteries for engine start and the bow thruster and windlass batteries through 32amp BtoBs. That ensures that these batteries are always fully charged. I also have switch to directly connect the domestic and starter batteries.

The LiFePO4 batteries are charged by 200W of solar through a MPPT charge controller.

Observations and comments?