Hurricane

Well-Known Member

Update

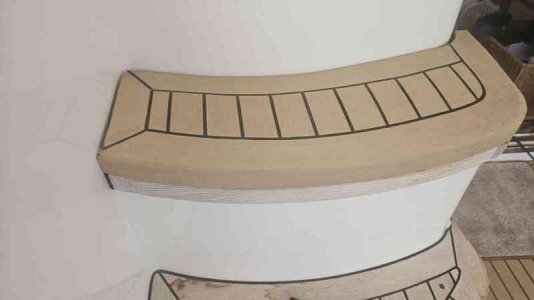

It took a couple of days longer than I thought to "cut in" the borders after making the panels at home over the winter months.

Weather was nice here in Spain most of the time so I set my workshop up in the open - on the pontoon.

This is the result so far.

Dry fitted - yet to be stuck down after the GRP repairs and smoothing done.

Top welding has come out OK.

The 5mm edges will be caulked after it has all been stuck down.

In the photos, you may see some lighter patches around the areas that I've sanded. These will "fade in" over time like the rest of the boat.

It is lovely to walk on - much smoother than the old wood teak - in fact as smooth as the wood teak was when it was new.

Plastic teak gets hotter than wood in the sun but it is really easy to keep clean.

And when you drop stuff on it (crisps etc) it just wipes clean.

I hope you find this thread interesting.

It took a couple of days longer than I thought to "cut in" the borders after making the panels at home over the winter months.

Weather was nice here in Spain most of the time so I set my workshop up in the open - on the pontoon.

This is the result so far.

Dry fitted - yet to be stuck down after the GRP repairs and smoothing done.

Top welding has come out OK.

The 5mm edges will be caulked after it has all been stuck down.

In the photos, you may see some lighter patches around the areas that I've sanded. These will "fade in" over time like the rest of the boat.

It is lovely to walk on - much smoother than the old wood teak - in fact as smooth as the wood teak was when it was new.

Plastic teak gets hotter than wood in the sun but it is really easy to keep clean.

And when you drop stuff on it (crisps etc) it just wipes clean.

I hope you find this thread interesting.