Nito

Well-Known Member

Hello folks,

From way back when I was researching buying a boat I came across the dreaded Diesel Bug topic. At the age of boats we were looking at and the nature of them meaning that removing tanks would be no easy job, I began looking at the options of how to deal with potential bug and came across the Diesel Dipper. MarShip - Diesel Dipper Fuel De-watering

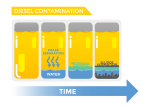

Anyway, fast forward to when we got our boat in May last year, it had previously had the fuel polished a couple of years prior and the primary filters all looked clear and good, despite the lockdowns, We embarked from Poole with a full tank and motored her around the coast leaving us with about a third of a tank. We brimmed it, so the fuel should have been fresh by all accounts. When we got to about half a tank later in the season, we began to have an intermittent drop in revs on one engine. It didn't happed while underway, it was upon throttling back and reapplying that it struck. At that point it just couldn't exceed 1600rpm. Then after throttle down and back up it would randomly pass. This happened a couple of times on the next couple of journeys but it would also not appear at all on other trips. The bowls all looked good. Anyway, a little while later I checked the filters and to my surprise they were covered in thick goo aka the bug. I've never had any water in the bowls and from a distance the bowls were a lovely clear red but up close there was some dark build up right at the bottom.

Whatever our problem may turn out to be, I would have to begin the troubleshooting with eradicating fuel quality as a suspect. It definitely wasn't inlet related, turbo spins freely and is clean, and no black smoke. So it's a fuel related issue, be it injectors, pumps, air in pipework, blocked lines, blocked fuel inlet tubes/strainers etc. A diesel dipper was always on the long range radar, because it would future proof the boat and take away the constant fear of picking up contaminated fuel. I have had diesel bug in my pickup truck in the past after picking up contaminated fuel and the whole tank had to be dropped and cleaned out, not a particularly viable option on our boat without removing the engines first.

I therefore got on the phone to the Diesel Dipper inventor Peter at Marship sooner than I'd have anticipated. After many emails and conversations he patiently answered all my questions and has been a pleasure to deal with. I went ahead and purchased one. (pic below shows custom fabricated mounting brackets, fuel hose and additional electrical wiring none of which is included with the dipper. There is also an adaptor and dip tube which isn't included but are available from Marship). Peter kindly also supplied the aluminium dip tube which is slash cut by 45 degrees at one end which sits on the tank base and his proprietary valve kit. I also purchased Marine 16 Diesel Bug Treatment and Diesel Injector Cleaner for good measure.

Theoretically it's an easy DIY fit, a 3/8 feed hose, 3/8 return hose and a positive and negative wire. Simples. Of course getting a suitable line in and out of the tank will be different for everyone. Marship simplify this by offering retro fit dip tubes where you simply make a hole in the top of your tank. Not a route I wanted to go down. We have two large aluminium tanks, totalling 990L of Diesel. There is a port and stbd one, connected by a large 1" line at their bases to keep the level equal in each and allowing them to be filled by deck fillers on either side. Fortunately for me, although Sunseeker tanks don't have a drain point or sump, these ones did have a pump out point which I discovered has a dip tube that sucks from 10mm off the bottom of the tank. According to Peter the dip tube should go to the bottom of the tank for maximum effect. Again by a stroke of luck, the internal bore of this dip tube is 10mm ID. This therefore allows a 10mm OD tube to fit down it which is the same diameter that Marship use with their dip tube. By using the right adapters I am able to use the compression fittings and valve that comes with the optional dipper 'valve kit'.

For the return, I decide the cleanest option will be to return the filtered diesel into the fuel filler hose. I buy some new hose and have a T piece fabricated in 51mm with a 3/8 barb.

I enlist my youngest who did a sterling job of getting to the difficult to access filler pipe. Dad was on hand to help him passing tools back and forth and he did me very proud. We managed to remove the old one, which had 1996 stamped on it, and use this to measure the new pipe introducing the T piece into it.

On top of the fuel tank is a well camouflaged child! Fortunately he’s able to just get in there but it’s tight.

The assembly is completed. New hose fitted, (the cable tie excess did get snipped!) and we’re all up and running…

Tadaa...Dipper installed on its custom brackets to the bulkhead uprights...

and the results below....

I cycle the tank for 4.5 hours in port, at 2 litres per minute flow rate, this will be sufficient to cycle the remaining 500 litres of diesel in the tank at least once. Above shows the gloop that it collected. The best way to describe it is like a thick gravy.

Shake it up and watch it slowly slime down the bottle. Gloopy, thick and something that will easily block filters. I presume it could limit flow if it clings around the strainers on the end of the fuel delivery pipe. I’m hoping this is the solution to our problem. Peter tells me that it’s out at sea that it really comes into its own, the movement of diesel sloshing around the tank at sea should unsettle much more. I ran it in port for curiosity and to give it a head start. Another hour running with the engines on too to create some turbulence in the tank and the dipper is running clean for the moment. I look forward to seeing what will happen at sea…this to be updated as it happens. For now, I’d say this is a good start for the dipper, whether it cures the issue or not remains to be seen but with the ongoing issues with diesel these days it will certainly future proof the quality of fuel for many years to come.

I'm looking forward to how much more it will catch at sea. One thing is for sure, I'd rather have this out of the tank than in it!! Fingers crossed it cures our running issue, if not it will mean moving on to the next step! Either way, it's comforting to have some control over the quality of our fuel.

From way back when I was researching buying a boat I came across the dreaded Diesel Bug topic. At the age of boats we were looking at and the nature of them meaning that removing tanks would be no easy job, I began looking at the options of how to deal with potential bug and came across the Diesel Dipper. MarShip - Diesel Dipper Fuel De-watering

Anyway, fast forward to when we got our boat in May last year, it had previously had the fuel polished a couple of years prior and the primary filters all looked clear and good, despite the lockdowns, We embarked from Poole with a full tank and motored her around the coast leaving us with about a third of a tank. We brimmed it, so the fuel should have been fresh by all accounts. When we got to about half a tank later in the season, we began to have an intermittent drop in revs on one engine. It didn't happed while underway, it was upon throttling back and reapplying that it struck. At that point it just couldn't exceed 1600rpm. Then after throttle down and back up it would randomly pass. This happened a couple of times on the next couple of journeys but it would also not appear at all on other trips. The bowls all looked good. Anyway, a little while later I checked the filters and to my surprise they were covered in thick goo aka the bug. I've never had any water in the bowls and from a distance the bowls were a lovely clear red but up close there was some dark build up right at the bottom.

Whatever our problem may turn out to be, I would have to begin the troubleshooting with eradicating fuel quality as a suspect. It definitely wasn't inlet related, turbo spins freely and is clean, and no black smoke. So it's a fuel related issue, be it injectors, pumps, air in pipework, blocked lines, blocked fuel inlet tubes/strainers etc. A diesel dipper was always on the long range radar, because it would future proof the boat and take away the constant fear of picking up contaminated fuel. I have had diesel bug in my pickup truck in the past after picking up contaminated fuel and the whole tank had to be dropped and cleaned out, not a particularly viable option on our boat without removing the engines first.

I therefore got on the phone to the Diesel Dipper inventor Peter at Marship sooner than I'd have anticipated. After many emails and conversations he patiently answered all my questions and has been a pleasure to deal with. I went ahead and purchased one. (pic below shows custom fabricated mounting brackets, fuel hose and additional electrical wiring none of which is included with the dipper. There is also an adaptor and dip tube which isn't included but are available from Marship). Peter kindly also supplied the aluminium dip tube which is slash cut by 45 degrees at one end which sits on the tank base and his proprietary valve kit. I also purchased Marine 16 Diesel Bug Treatment and Diesel Injector Cleaner for good measure.

Theoretically it's an easy DIY fit, a 3/8 feed hose, 3/8 return hose and a positive and negative wire. Simples. Of course getting a suitable line in and out of the tank will be different for everyone. Marship simplify this by offering retro fit dip tubes where you simply make a hole in the top of your tank. Not a route I wanted to go down. We have two large aluminium tanks, totalling 990L of Diesel. There is a port and stbd one, connected by a large 1" line at their bases to keep the level equal in each and allowing them to be filled by deck fillers on either side. Fortunately for me, although Sunseeker tanks don't have a drain point or sump, these ones did have a pump out point which I discovered has a dip tube that sucks from 10mm off the bottom of the tank. According to Peter the dip tube should go to the bottom of the tank for maximum effect. Again by a stroke of luck, the internal bore of this dip tube is 10mm ID. This therefore allows a 10mm OD tube to fit down it which is the same diameter that Marship use with their dip tube. By using the right adapters I am able to use the compression fittings and valve that comes with the optional dipper 'valve kit'.

For the return, I decide the cleanest option will be to return the filtered diesel into the fuel filler hose. I buy some new hose and have a T piece fabricated in 51mm with a 3/8 barb.

I enlist my youngest who did a sterling job of getting to the difficult to access filler pipe. Dad was on hand to help him passing tools back and forth and he did me very proud. We managed to remove the old one, which had 1996 stamped on it, and use this to measure the new pipe introducing the T piece into it.

On top of the fuel tank is a well camouflaged child! Fortunately he’s able to just get in there but it’s tight.

The assembly is completed. New hose fitted, (the cable tie excess did get snipped!) and we’re all up and running…

Tadaa...Dipper installed on its custom brackets to the bulkhead uprights...

and the results below....

I cycle the tank for 4.5 hours in port, at 2 litres per minute flow rate, this will be sufficient to cycle the remaining 500 litres of diesel in the tank at least once. Above shows the gloop that it collected. The best way to describe it is like a thick gravy.

Shake it up and watch it slowly slime down the bottle. Gloopy, thick and something that will easily block filters. I presume it could limit flow if it clings around the strainers on the end of the fuel delivery pipe. I’m hoping this is the solution to our problem. Peter tells me that it’s out at sea that it really comes into its own, the movement of diesel sloshing around the tank at sea should unsettle much more. I ran it in port for curiosity and to give it a head start. Another hour running with the engines on too to create some turbulence in the tank and the dipper is running clean for the moment. I look forward to seeing what will happen at sea…this to be updated as it happens. For now, I’d say this is a good start for the dipper, whether it cures the issue or not remains to be seen but with the ongoing issues with diesel these days it will certainly future proof the quality of fuel for many years to come.

I'm looking forward to how much more it will catch at sea. One thing is for sure, I'd rather have this out of the tank than in it!! Fingers crossed it cures our running issue, if not it will mean moving on to the next step! Either way, it's comforting to have some control over the quality of our fuel.

Last edited: