Tranona

Well-Known Member

I have already explained it. The anode needs to be in the same water (electrolyte) as the bits it is protecting. The anode in your engine cooling system is there to protect metals in the cooling system that have different potentials. Zinc has low potential so erodes rather than the other metal. Your hull anode is NOT in the same water as the cooling water in the engine.You'll need to explain that to me in wee words .

My shaft anode appears to have looked after my prop perfectly well.

The engine is wired to the hull anode and appears to have suffered no ill effects in the several decades I've owned it.

Given that it's raw water cooled, then isn't it effectively in the required electrolyte?

I was told many years ago by a naval architect that anodising a vessel was a black art .

This explains how galvanic cells work en.wikipedia.org/wiki/Galvanic_cell and this explains how sacrificial anodes are used to prevent corrosion mgduff.co.uk/knowledge-base/cathodic-protection

With regards to your engine the makers clearly believe that there are metals in the raw water cooling circuit of different potential that represent a potential corrosion problem from galvanic action and that a sacrificial anode will reduce or prevent this. If this were not the case why would they bother. Many engines do not have internal anodes - all small modern Volvos for example because their heat exchangers do not have metals of different potential in the seawater side.

The hull anode may be connected to the engine, but that is normally to make a circuit to the shaft and propeller. The anode is in the circuit to stop dezincification of the propeller. To be effective it has to be electrically connected to the shaft and position close by in line of sight with the propeller. Alternatively if there is exposed shaft, for example if a P bracket is used to support the shaft, a shaft anode can be used instead as in your case. this suggests your hull anode serves no purpose and could be removed. It is definitely not a substitute for the engine anode.

There is no "black art" about using anodes, but a high level of misunderstanding or even ignorance among many including regrettably some surveyors. The principles are very simple - dissimilar metals in electrical contact in water, which is an electrolyte, particularly seawater. On a typical small sailing boat the main items that need protection are propellers, saildrive housings, bow thrusters and in some cases rudder stocks and fittings. As already suggested engines vary, but if an anode is needed the maker will fit one.

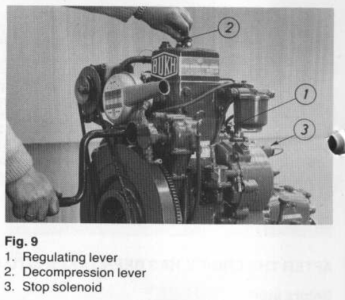

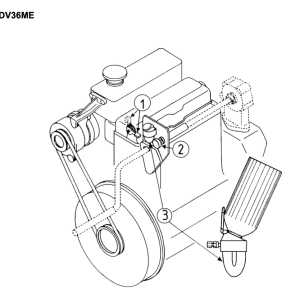

My boat is just about as complicated as you can get for a shaft drive sailing boat. The Beta engine has an anode in the heat exchanger. The shaft is stainless and the feathering propeller is a mixture of yellow metal (bronze) and stainless. The propeller has its own anode, but its size is limited so a hull anode is fitted as a backup. It is not connected to the engine because there is a flexible coupling so the circuit to the propeller is made through a contact running on the shaft. The photos show how it works. The first is the hull anode close to the propeller, second is the propeller with the anode on the end of the hub and the third is the connection to the shaft.