VandKoala

Active Member

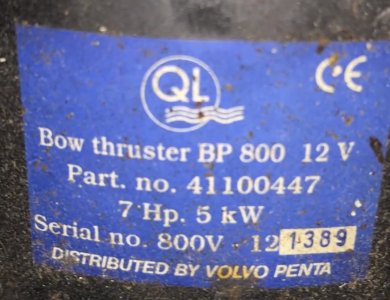

Hi, last weekend our old 5kw bow prop started only working to one side (of course while blowing 20knots from the “wrong” side)

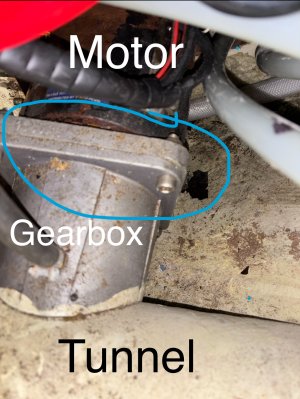

To starboard - only trickling sound and almost no trust. To port gives ok trust. You can hear the difference in the video.

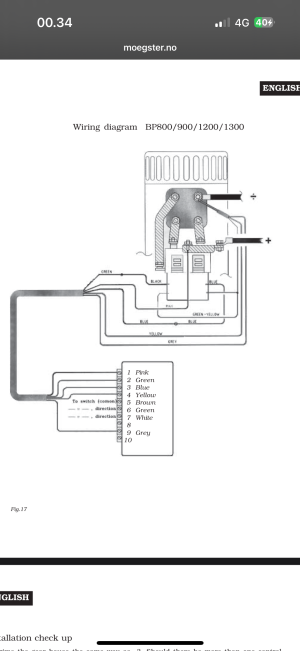

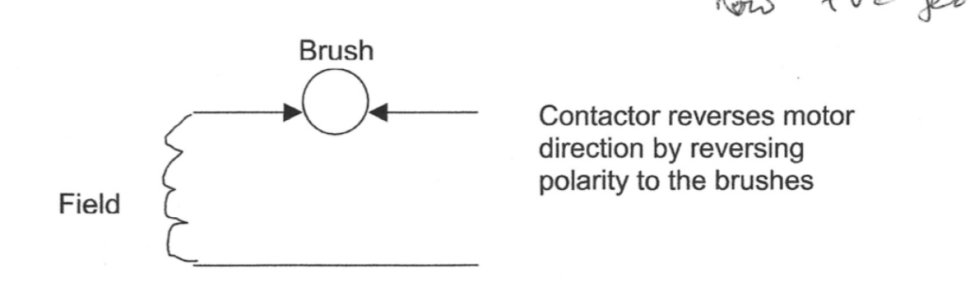

Where do I start looking?

Thanks!

To starboard - only trickling sound and almost no trust. To port gives ok trust. You can hear the difference in the video.

Where do I start looking?

Thanks!