ritchyp

Well-Known Member

Hi,

During the weekend just passed, I decided to remove the heat exchanger on my Beta marine 30 engine and clean it out.

About 6 weeks ago we accidentally ran into a mud bank whilst tacking up Southampton water close to low tide. My yacht draws 1.8 m but with the fuel and both water tanks full and carrying tools, food and other equipment, plus crew, I call it 2.0m. We ran into a mud bank just before I tacked and got stuck for half an hour until the tide turned and we floated enough to reverse out . Whilst initially trying to reverse out under full power when we got stuck, I believe I sucked up a lot of mud and silt which caused a partial blockage in the raw water circulation. After that the engine always ran too hot but I saw the temperature warning light come on or have and the alarm beeper come on but it just smelled and felt to the touch like it was running too hot. There was water coming out of the exhaust but not as much as the manual says it should which is 2.0 L every 10 seconds. This I never measured but I never had a cooling problem before the incident. When I got back to the berth to leave for home, I took the cover off to turnoff the seacock and there was a big pool of rusty water in the engine bilge and the engine was very, very hot.

After flushing out the fresh water system and bleeding out the water until it ran clean. I drained it and refilled it with new coolant. It made no difference at all but at least the fresh water coolant was not rusty. I decided after reading the engine manual and getting an understanding of how the cooling system works, that the heat exchanger must be clogged up with mud and silt still so removed the rods and put then in a bucket of water with a strong de-scaler in it to soften any calcium deposits. This was all done successfully and on the back of the engine where the cap end has the anode and two pipe inlets/outlets. One of them was caked up with limescale so badly that opening was only about 6mm so we cleaned all that out until the bore of the outlet was restored back to its normal size.

It was all reassembled properly and a new anode fitted and yet more new coolant filled up to the maximum level. Before we started the engine, I filled up the raw water strainer with water so the impeller would not run dry initially but did not get any water out of the exhaust. Water was coming through the strainer so I thought it was purging the air and water would come through eventually and after a while it did but not enough and even as much as it was before we started. I decide to stop the engine and scour the manual for information but it said it was self bleeding so I started the engine and let it run for 5 minutes and the amount of water spitting from the exhaust seemed to be getting better so I thought that it was sorted and tidied up as we were going to go for a day sail on Sunday as the weather had improved and the boat needed a sea trial as I have fitted new instruments and transducers and had a lift out clean and antifoul. The last 6 weeks has been all work and no sailing.

It is worth mentioning a couple of things. Firstly, the boat was on the hard for 24 hours whilst we cleaned and antifouled her. The water from the raw water side of the cooling system must have drained out through the grill uptake on the bottom of the hull. When we were relaunched, they lowered us into the water stern end first to allow the raw water cooling system to fill up with water. It took a long time but eventually water started to come out of the exhaust so off we went to the berth briefly.

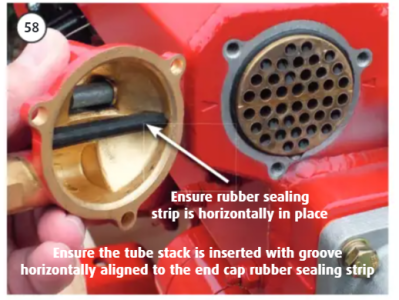

Secondly, after the aborted sea trial due to the alarm coming from the starter box and tacho. Later on that afternoon as we were packing to leave, my friend who was helping me to clean to the heat exchanger asked me for the manual which I gave him and he said I think I put the heat exchanger in upside down. I said do you mean the wrong around and he said no but 180 degrees the wrong way. It has alignment marks on it and on the engine so you get the rotation of it lined up correctly but looking at the diagram in the book, I believe I have re-fitted it 180 degrees out......? Then later on he said Actually I am not sure if it would go in upside down and if it went in without any resistance, and if the marks were lined up correctly, I don't think it would make any difference.

So after all that work and all the other work done over the last 6 weeks, I still have a boat that has a a fairly serious fault. Could the heat exchanger be the culprit or is there a way to purge the air locks (If there are any) I am stumped, we all are.

Anybody have any ideas please?

During the weekend just passed, I decided to remove the heat exchanger on my Beta marine 30 engine and clean it out.

About 6 weeks ago we accidentally ran into a mud bank whilst tacking up Southampton water close to low tide. My yacht draws 1.8 m but with the fuel and both water tanks full and carrying tools, food and other equipment, plus crew, I call it 2.0m. We ran into a mud bank just before I tacked and got stuck for half an hour until the tide turned and we floated enough to reverse out . Whilst initially trying to reverse out under full power when we got stuck, I believe I sucked up a lot of mud and silt which caused a partial blockage in the raw water circulation. After that the engine always ran too hot but I saw the temperature warning light come on or have and the alarm beeper come on but it just smelled and felt to the touch like it was running too hot. There was water coming out of the exhaust but not as much as the manual says it should which is 2.0 L every 10 seconds. This I never measured but I never had a cooling problem before the incident. When I got back to the berth to leave for home, I took the cover off to turnoff the seacock and there was a big pool of rusty water in the engine bilge and the engine was very, very hot.

After flushing out the fresh water system and bleeding out the water until it ran clean. I drained it and refilled it with new coolant. It made no difference at all but at least the fresh water coolant was not rusty. I decided after reading the engine manual and getting an understanding of how the cooling system works, that the heat exchanger must be clogged up with mud and silt still so removed the rods and put then in a bucket of water with a strong de-scaler in it to soften any calcium deposits. This was all done successfully and on the back of the engine where the cap end has the anode and two pipe inlets/outlets. One of them was caked up with limescale so badly that opening was only about 6mm so we cleaned all that out until the bore of the outlet was restored back to its normal size.

It was all reassembled properly and a new anode fitted and yet more new coolant filled up to the maximum level. Before we started the engine, I filled up the raw water strainer with water so the impeller would not run dry initially but did not get any water out of the exhaust. Water was coming through the strainer so I thought it was purging the air and water would come through eventually and after a while it did but not enough and even as much as it was before we started. I decide to stop the engine and scour the manual for information but it said it was self bleeding so I started the engine and let it run for 5 minutes and the amount of water spitting from the exhaust seemed to be getting better so I thought that it was sorted and tidied up as we were going to go for a day sail on Sunday as the weather had improved and the boat needed a sea trial as I have fitted new instruments and transducers and had a lift out clean and antifoul. The last 6 weeks has been all work and no sailing.

It is worth mentioning a couple of things. Firstly, the boat was on the hard for 24 hours whilst we cleaned and antifouled her. The water from the raw water side of the cooling system must have drained out through the grill uptake on the bottom of the hull. When we were relaunched, they lowered us into the water stern end first to allow the raw water cooling system to fill up with water. It took a long time but eventually water started to come out of the exhaust so off we went to the berth briefly.

Secondly, after the aborted sea trial due to the alarm coming from the starter box and tacho. Later on that afternoon as we were packing to leave, my friend who was helping me to clean to the heat exchanger asked me for the manual which I gave him and he said I think I put the heat exchanger in upside down. I said do you mean the wrong around and he said no but 180 degrees the wrong way. It has alignment marks on it and on the engine so you get the rotation of it lined up correctly but looking at the diagram in the book, I believe I have re-fitted it 180 degrees out......? Then later on he said Actually I am not sure if it would go in upside down and if it went in without any resistance, and if the marks were lined up correctly, I don't think it would make any difference.

So after all that work and all the other work done over the last 6 weeks, I still have a boat that has a a fairly serious fault. Could the heat exchanger be the culprit or is there a way to purge the air locks (If there are any) I am stumped, we all are.

Anybody have any ideas please?

Last edited: