Tranona

Well-Known Member

Have you taken the pipe off from the pump to the HE? The system IS self priming provided the seawater pump is in good order. As a number of us have said you need to open the system up at every joint to see where the blockage is. You won't get airlocks because there is nowhere for air to get in.

Would help if you posted some photos rather than long explanations that don't help visualise your exact setup.

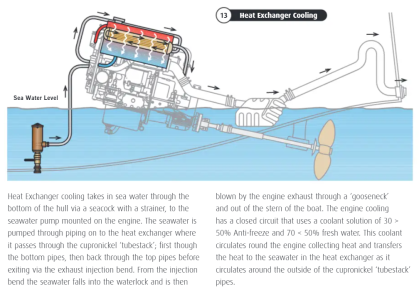

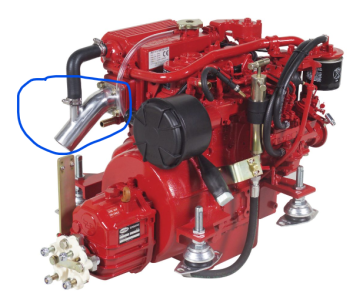

My guess from what you have written is that you have a ball valve inlet with an external grill then a strainer (attached to the top?) then a hose to the inlet of the seawater pump, then the long pipe that goes over the top of the engine to the HE. The outlet from the HE then goes up to an antisyphon and down to the injection point in the exhaust outlet.

You need to check that you are getting good flow at all of those points. So detach the hose into the pump with the seacock open. There should be a rush of water. Shut the seacock, reconnect the hose start the engine and disconnect the hose from the outlet to the pump. You should get a good flow of water. Shut down the engine. Reconnect the outlet, start engine and raise the revs a bit and disconnect the inlet to the HE. you should get a good flow of water there. If not the blockage is in the pipe. If good flow there then the blockage is in the HE or the outlet to the antisyphon and exhaust.

Following this kind of process is the only way.

The engine is overheating because there is insufficient seawater flow to cool the the engine coolant.

Would help if you posted some photos rather than long explanations that don't help visualise your exact setup.

My guess from what you have written is that you have a ball valve inlet with an external grill then a strainer (attached to the top?) then a hose to the inlet of the seawater pump, then the long pipe that goes over the top of the engine to the HE. The outlet from the HE then goes up to an antisyphon and down to the injection point in the exhaust outlet.

You need to check that you are getting good flow at all of those points. So detach the hose into the pump with the seacock open. There should be a rush of water. Shut the seacock, reconnect the hose start the engine and disconnect the hose from the outlet to the pump. You should get a good flow of water. Shut down the engine. Reconnect the outlet, start engine and raise the revs a bit and disconnect the inlet to the HE. you should get a good flow of water there. If not the blockage is in the pipe. If good flow there then the blockage is in the HE or the outlet to the antisyphon and exhaust.

Following this kind of process is the only way.

The engine is overheating because there is insufficient seawater flow to cool the the engine coolant.