PetiteFleur

Well-Known Member

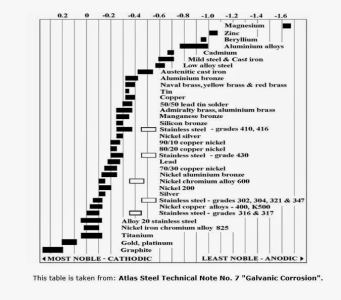

Just fitted new galvanised rowlocks and sockets, replacing very rusty ones. What screws should I use to prevent corrosion?

I used stainless A2 screws but worried it will cause corrosion.

I used stainless A2 screws but worried it will cause corrosion.