[2574]

...

We have recently had a serious problem arise with the Aquadrive fitting in our gearbox-to-propellor drivetrain. If you have an Aquadrive fitting in your boat the below will be of interest - otherwise ignore the following!

Back in 2020 we collected our new to us yacht for the delivery trip home. I noticed a line of splattered grease perpendicular to the Aquadrive that had evidently been spun off the unit by centrifugal force. I also noticed three of the six bolts on the forward hub of the Aquadrive were finger loose and falling out. I tightened the bolts with an Allen key, cleaned up the previously splatted grease and thought nothing further of it.

Fast forward to current day. We had a leaking shaft seal and instructed an engineer to replace the seal. This required dismantling the Aquadrive to push the shaft back. When the engineer removed the Aquadrive he found the internal bolts which serve to fix the shaft to the aft Aquadrive hub were also loose. This had caused the shaft to be loose in the Aquadrive fitting which has caused internal movement and the deformation of the forward end of the propshaft. New propshaft required. As an aside we have also had to replace cutless bearing, thrust bearing and seal housing (and seal) but that’s not directly related to the Aquadrive problem.

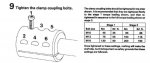

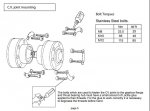

The Aquadrive was found to have wear in the gearing and it was recommended that it be replaced. I met with experts on Aquadrive to collect the parts and was given very useful guidance on the fitting of the Aquadrive unit. It is absolutely essential that all bolts are torqued to specification and are fitted with thread locking substance. The consequences of not fitting to specification can be catastrophic. The experts advised that a splattering of grease is always an indication of loose Aquadrive bolts and it is essential that it be rectified immediately.

In conversation with other owners (in our online group ) it seems to be a problem more common than one might expect. It seems from the feedback that where Aquadrive units are dissasembled for shaft seal replacement the unit is then often not refitted correctly. I’m guessing that the engineer doing this work doesn’t have the fitting guidance to hand and consequently the problem arises.

There are various case reports online where the shaft has become so loose in the Aquadrive hub that it has fallen out, slid back through the thrust bearing, out past the seal and jambed the rudder or fallen out of the hull completely. In one instance where the shaft released and jambed the rudder on full lock the yacht could not be sailed or towed (except in circles) leading to abandonment and sinking, it’s a serious issue.

So, if you have n Aquadrive - keep an eye to the bolts. If any are loose then remove, degrease, apply thread locker and torque up.

Hope this avoids a future problem for someone.

Rob

Back in 2020 we collected our new to us yacht for the delivery trip home. I noticed a line of splattered grease perpendicular to the Aquadrive that had evidently been spun off the unit by centrifugal force. I also noticed three of the six bolts on the forward hub of the Aquadrive were finger loose and falling out. I tightened the bolts with an Allen key, cleaned up the previously splatted grease and thought nothing further of it.

Fast forward to current day. We had a leaking shaft seal and instructed an engineer to replace the seal. This required dismantling the Aquadrive to push the shaft back. When the engineer removed the Aquadrive he found the internal bolts which serve to fix the shaft to the aft Aquadrive hub were also loose. This had caused the shaft to be loose in the Aquadrive fitting which has caused internal movement and the deformation of the forward end of the propshaft. New propshaft required. As an aside we have also had to replace cutless bearing, thrust bearing and seal housing (and seal) but that’s not directly related to the Aquadrive problem.

The Aquadrive was found to have wear in the gearing and it was recommended that it be replaced. I met with experts on Aquadrive to collect the parts and was given very useful guidance on the fitting of the Aquadrive unit. It is absolutely essential that all bolts are torqued to specification and are fitted with thread locking substance. The consequences of not fitting to specification can be catastrophic. The experts advised that a splattering of grease is always an indication of loose Aquadrive bolts and it is essential that it be rectified immediately.

In conversation with other owners (in our online group ) it seems to be a problem more common than one might expect. It seems from the feedback that where Aquadrive units are dissasembled for shaft seal replacement the unit is then often not refitted correctly. I’m guessing that the engineer doing this work doesn’t have the fitting guidance to hand and consequently the problem arises.

There are various case reports online where the shaft has become so loose in the Aquadrive hub that it has fallen out, slid back through the thrust bearing, out past the seal and jambed the rudder or fallen out of the hull completely. In one instance where the shaft released and jambed the rudder on full lock the yacht could not be sailed or towed (except in circles) leading to abandonment and sinking, it’s a serious issue.

So, if you have n Aquadrive - keep an eye to the bolts. If any are loose then remove, degrease, apply thread locker and torque up.

Hope this avoids a future problem for someone.

Rob