zoidberg

Well-known member

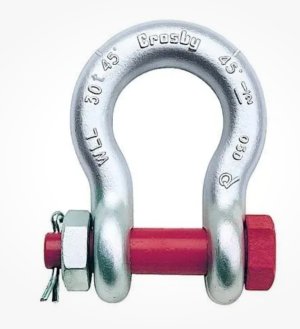

I'm more than a little pleased to be able to advise completion of my revised anchoring setup, with the delivery of a set of Crosby chain connectors and Green Pin shackles to complement the reel of hi-strength Grade 80 6mm proof-tested Crosby chain that turned up earlier.

This now permits me to ship my 2 Fortress Fx-16s with my Spade S80, each with its own length of chain and 150' rope-rode, ready for deployment each in its own tidy stowage bag. The setup is tested to 4.4T, with certification, and the chain is half the weight of my previous 10mm G30 stuff, while giving about the same strength. Given my 27' boat weighs in at about 3.5T, that's far more than is ever likely to be generated.

Essentially, I've reduced the weight of chain I have to carry, and haul back on board manually, by 1 kilo per metre. Which is, for an ould bugr, significant.

The astute and eagle-eyed will note the tiny locking pin is not yet inserted into the Crosby link, nor the wire-/cabletie-locking in place on the shackle pin - and also the polyprop bag which holds the disassembled anchor tidily when stowed.

I'm grateful to Jon Neeves for his guidance as 'anchoring guru' and for the bonnie lass at CWS Lifting who 'held my hand' through the procurement process.

This now permits me to ship my 2 Fortress Fx-16s with my Spade S80, each with its own length of chain and 150' rope-rode, ready for deployment each in its own tidy stowage bag. The setup is tested to 4.4T, with certification, and the chain is half the weight of my previous 10mm G30 stuff, while giving about the same strength. Given my 27' boat weighs in at about 3.5T, that's far more than is ever likely to be generated.

Essentially, I've reduced the weight of chain I have to carry, and haul back on board manually, by 1 kilo per metre. Which is, for an ould bugr, significant.

The astute and eagle-eyed will note the tiny locking pin is not yet inserted into the Crosby link, nor the wire-/cabletie-locking in place on the shackle pin - and also the polyprop bag which holds the disassembled anchor tidily when stowed.

I'm grateful to Jon Neeves for his guidance as 'anchoring guru' and for the bonnie lass at CWS Lifting who 'held my hand' through the procurement process.

Last edited: